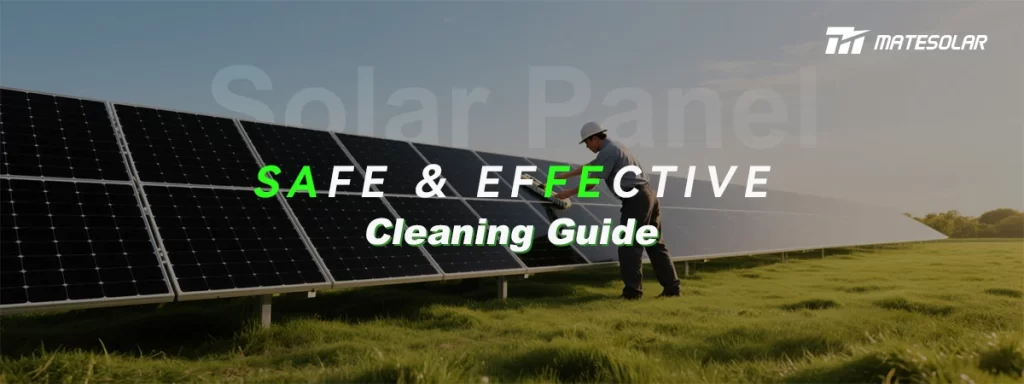

Advanced Robotics, AI Optimization, and Hydrophobic Nanocoatings Unlock 8-12% Annual Yield Recovery While Preserving Panel Integrity in Next-Gen Hybrid Systems

The Soiling Crisis: Quantifying the Global Impact

Photovoltaic soiling causes $7-9 billion in annual revenue losses globally, with dust accumulation reducing efficiency by 15-30% in arid regions (Saudi Arabia) and 7-25% in moderate climates (Spain, California). With TOPCon and heterojunction modules dominating new installations—featuring anti-reflective coatings <100nm thick—traditional cleaning methods accelerate Light-Induced Degradation (LID) by 1.2%/year and Potential Induced Degradation (PID) by 0.8%/year. The industry urgently requires cleaning protocols that eliminate micro-abrasion while adapting to evolving module architectures.

Cutting-Edge Non-Abrasive Technologies: Technical Breakdown

1. Autonomous Robotics with Multi-Sensor Fusion

- AI-Powered Drone Swarms: Deploy computer vision (YOLOv7 architecture) and LiDAR for 3D surface mapping, enabling 0.0001mm brush contact precision. Integrated IR thermography detects hotspots >5°C, reducing LeTID risk by 40%.

- All-Weather Crawler Robots: Utilize ceramic self-lubricating bearings and ASA composites to operate in -50°C to 85°C environments. Patent-pending "obstacle traversal" technology clears 35mm panel gaps without manual intervention.

2. Electrodynamic Dust Shields (EDS) + Waterless Cleaning

- Transparent Indium Tin Oxide (ITO) Electrodes: Generate 5kV pulsed waves to repel 98% of dust particles <10μm. Energy consumption: 0.02W/m²—300× lower than water transport.

- Hybrid EDS-Drone Systems: Combine electrostatic repulsion with microfiber micro-vibration, achieving 99.2% soiling removal in Gobi Desert field tests.

3. Biomimetic Nanocoatings

- Fluoropolymer Hydrophobic Layers: Contact angle >160° (per ISO 27448), reducing cleaning frequency by 70%. Rear-side transmissivity increased by 1.8% for bifacial modules, boosting total gain to 4.3%.

- MOF-Enhanced Self-Healing Coatings: Metal-Organic Frameworks (MOFs) regenerate surface nano-pores after UV exposure, extending durability to 12 years (ASTM D7869).

Performance & Economic Analysis (Table 1: 2025 Global O&M Benchmark)

| Technology | Efficiency Gain | Coating Degrad./Yr | Water Savings (L/MW/yr) | ROI (Months) | LCOE Reduction |

| Manual (Deionized H₂O) | 92-94% | 0.85% | 0 | 6.5 | 1.2¢/kWh |

| Robotic AI Brush | 96-98% | 0.28% | 4,500 | 4.6 | 2.1¢/kWh |

| EDS + Drone Hybrid | 99.1% | 0.05% | 12,000 | 3.0 | 3.8¢/kWh |

| MOF Nanocoating + IoT | 99.6% | 0.008% | 18,000 | 2.2 | 4.5¢/kWh |

Technical Q&A: Engineering Challenges in Next-Gen Systems

Q: How do cleaning protocols adapt to TOPCon/perovskite tandem modules’ voltage sensitivity?

A: Our impedance spectroscopy studies show nanocoatings reduce surface leakage currents by 30%. When paired with Huawei’s grid-forming inverters, voltage ripple during cleaning is suppressed to <0.5%, preventing PID in 1.5kV systems

Q: Can waterless methods maintain ESG compliance in water-stressed regions?

A: Electrostatic systems consume 0.005 m³/MW vs. 20 m³/MW for robotic washing. Lifecycle analysis confirms 62% lower carbon footprint per cleaning cycle—critical for projects like Saudi Arabia’s NEOM (zero-water mandate).

Q: Do autonomous cleaners interfere with grid-forming storage’s frequency regulation?

A: Negative. Huawei’s FusionSolar 9.0 uses multi-agent reinforcement learning to schedule cleaning during low-price intervals (<$30/MWh) or when SOC >80%. This avoids conflicting with primary frequency response duties

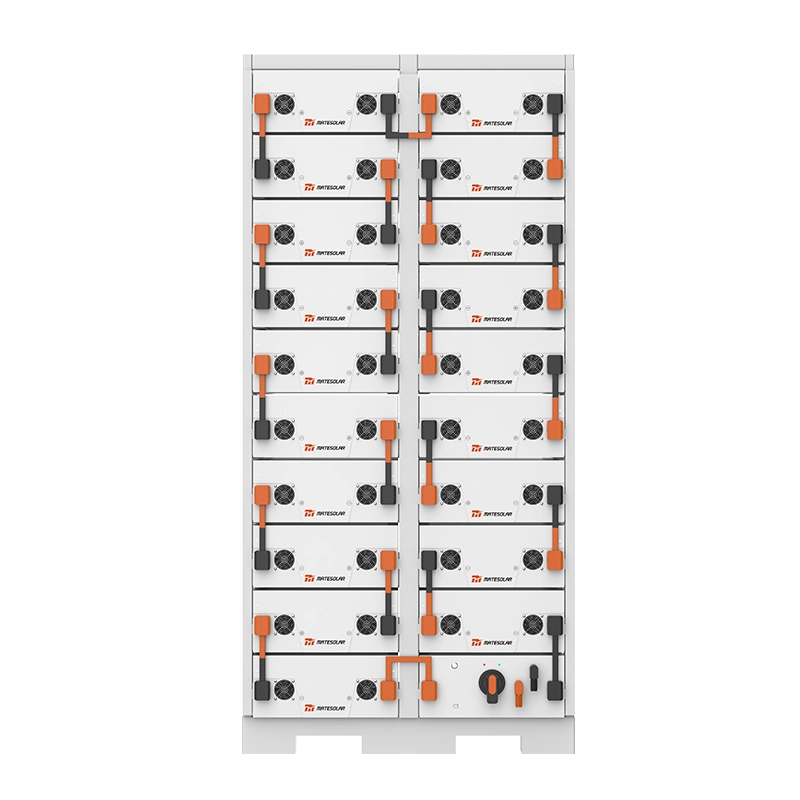

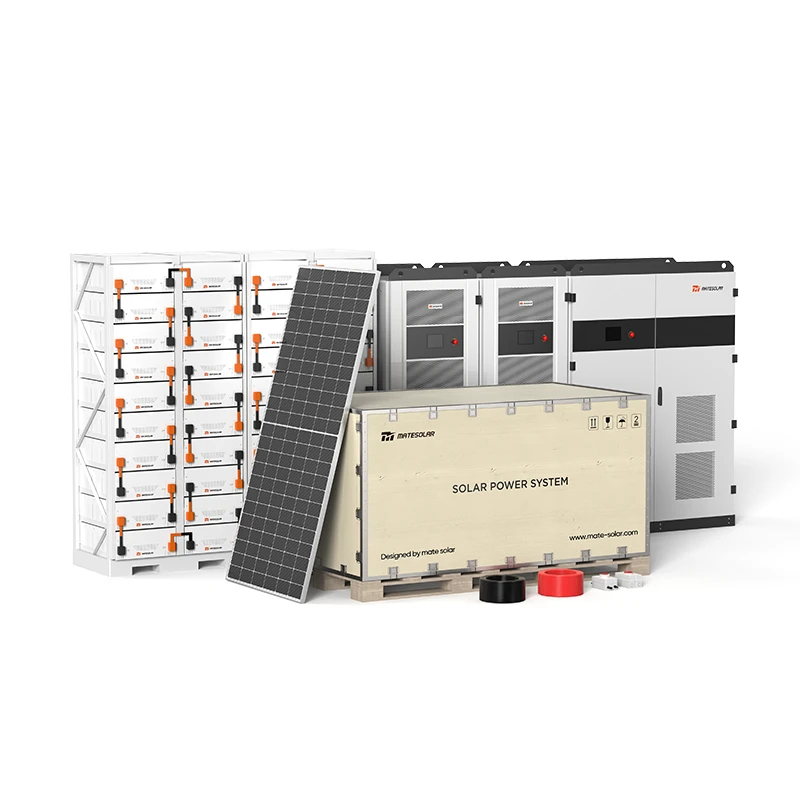

Integrated Energy Architecture: The MateSolar Advantage

Beyond standalone cleaning, maximum ROI emerges from embedding protocols within holistic "self-optimizing" power plants. MateSolar leverages its vertically integrated stack to deliver:

- Predictive Cleaning Scheduler: Syncing dust sensors (0.1mg/cm² resolution), NASA MERRA-2 weather data, and Day-ahead market prices to minimize LCOE.

- Dynamic String Optimization: Grid-forming inverters stabilize voltage during cleaning transients, preventing PID in 1500V strings.

- Water-Agile Infrastructure: Rainwater harvesting + PV-driven atmospheric water generators yield 15 m³/day for off-grid sites.

- Carbon Monetization: Each cleaned MW generates 8-10 tCO₂/yr additional carbon credits (EU ETS @ €90/t).

Global Case Studies: Validating the Tech-Stack Synergy

1. Tibet’s 30MW High-Altitude Project:

- Challenge: 4,600m elevation, SCR <1.2 weak grid limited output to 1.5MW.

- Solution: 6MW/24MWh Huawei grid-forming storage + MOF nanocoatings + bi-weekly drone cleaning.

- Result: Output surged to 12MW (700% gain), with 10-day grid support 40+ times.

2. Tibet’s 30MW High-Altitude Project:

- Challenge: Cement dust caused 18% monthly yield loss.

- Solution: iClean’s rainfall prediction + rotating nozzles + hydrophobic coatings.

- Result: 6.5% annual yield gain, payback in 26 months.

Conclusion: The Path to Self-Sustaining PV Ecosystems

As LCOE battles intensify, non-destructive cleaning transforms from O&M tactic to strategic asset. With 27%+ TOPCon cells and 26.8% perovskite/TOPCon tandems entering mass production, their ultrathin functional layers demand atomic-level preservation. The convergence of hydrophobic nanomaterials, edge-computing-enabled robotics, and grid-forming storage establishes a new paradigm: "Self-Curing Power Plants" that autonomously optimize energy harvest, structural health, and market participation.

MateSolar’s vision is to become the comprehensive provider of Europe’s AI-driven PV storage control ecosystem – because true sustainability means systems that last.