The global energy storage landscape is undergoing a transformative shift as liquid cooling containerized solutions emerge as the new standard for commercial and industrial (C&I) applications. With technological advancements accelerating at an unprecedented pace, these sophisticated systems are redefining performance parameters for energy density, lifespan, and safety in renewable energy storage.

Technological Breakthroughs in Liquid Cooling Containerized Storage

The energy storage industry has witnessed remarkable innovations in liquid cooling technology throughout 2025. Leading manufacturers have pushed the boundaries of what's possible with containerized storage systems:

Ganfeng Lithium Energy's groundbreaking 6.25MWh liquid cooling energy storage system represents the cutting edge of containerized storage technology. Featuring a massive 587Ah battery cell capacity, the system achieves an impressive volumetric energy density of 146Wh/L while improving integration efficiency by 25%. The company's innovative "checkerboard" square array layout has enabled the construction of 100MWh power plants that require 38% less land area compared to conventional solutions.

Inner Mongolia Zhongdian Energy Storage has contributed to this technological revolution with their patented liquid cooling lithium battery energy storage container, which features advanced wiring mechanisms that separate high and low voltage lines to prevent mutual interference and significantly enhance safety and maintenance convenience.

Easyat Group's 6.7MW/26.8MWh centralized liquid cooling containerized system specifically addresses the growing demand for long-duration energy storage (4 hours and above), which has been identified by China's National Development and Reform Commission as a core support for new power systems.

Comparative Analysis: Liquid Cooling vs. Traditional Air Cooling

To understand the significant advantages of liquid cooling technology, we must examine how it compares to the established air cooling approach across several critical parameters:

Table 1: Performance Comparison Between Liquid Cooling and Air Cooling Energy Storage Systems.

| Parameter | Liquid Cooling System | Air Cooling System | Advantage Ratio |

| Heat Transfer Efficiency | 1000-50000 W/m²K | 25-100 W/m²K | 6x for liquid cooling |

| Temperature Control Precision | ≤3°C | ≥5°C | 40% more precise |

| Cycle Life | Up to 15,000 cycles | Typically 6,000-8,000 cycles | 2x longer lifespan |

| System Lifespan | Over 20 years | Typically 10-15 years | 30-50% longer |

| Volume Energy Density | Up to 146 Wh/L | Typically 80-100 Wh/L | 40-50% higher |

| Installation Area Requirement | Reduced by 25-38% | Standard requirement | 25-38% savings |

| Operating Temperature Range | -40°C to 60°C | -20°C to 45°C | Wider range |

| Maintenance Requirements | 95% fewer rotating components | Multiple fans required | Significant reduction |

Superior Thermal Management Performance

Liquid cooling technology's most significant advantage lies in its thermal management capabilities. The fundamental difference stems from the heat transfer properties of liquids versus air. Liquids possess substantially higher thermal conductivity and heat capacity compared to gases, enabling more efficient heat absorption and dissipation from battery cells during high-power charging and discharging cycles.

This enhanced thermal performance translates to practical benefits for energy storage system operators. Liquid cooling maintains exceptional temperature uniformity across all battery cells in a system, typically within 3°C compared to the 5-10°C variations common in air-cooled systems. This precise temperature control extends battery cycle life by preventing localized hot spots that accelerate degradation.

Safety Enhancements

Safety represents another critical advantage of liquid cooling containerized systems. The completely sealed design of liquid cooling packs achieves IP65 protection, preventing the ingress of dust and moisture that can compromise electrical systems. This feature is particularly valuable for systems deployed in coastal areas with salt spray or desert environments with fine dust particles.

Many modern liquid cooling systems incorporate multi-level safety mechanisms that address thermal runaway risks at different system scales. Ganfeng's design exemplifies this approach with four layers of protection: cell-level, module-level, cabin-level, and system-linked fire suppression.

Long-Term Economic Advantages

While the initial investment for liquid cooling systems is approximately 1.5% higher than air cooling alternatives (1.35RMB/Wh vs. 1.33RMB/Wh), the long-term economic benefits are substantial and compelling for investors:

1. Extended Service Life: Systems lasting over 20 years provide additional years of revenue generation compared to air-cooled alternatives;

2. Reduced Maintenance Costs: With 95% fewer rotating components than air-cooled systems, liquid cooling solutions require less maintenance and experience fewer failures;

3. Superior Energy Efficiency: Lower internal energy consumption improves overall system efficiency and reduces operating costs;

4. Space Optimization: Higher power density translates to either more capacity in the same footprint or the same capacity in a smaller space, reducing land rental costs.

Diverse Market Applications and Implementation Scenarios

Liquid cooling containerized energy storage systems have demonstrated exceptional versatility across numerous application scenarios:

Large-Scale Centralized Energy Storage Power Stations

The technology is particularly suited for utility-scale applications where reliability, efficiency, and space optimization are critical. These systems can be deployed in diverse terrains ranging from deserts to mountainous regions, supporting the integration of renewable energy sources into main grids.

Commercial and Industrial Peak-Valley Electricity Price Arbitrage

For C&I applications, liquid cooling containers enable businesses to significantly reduce electricity costs by storing energy during low-rate periods and discharging during high-rate periods. The technology's high efficiency ensures maximum cost savings, with some installations reporting a 15% reduction in levelized cost of electricity (LCOE).

Renewable Energy Integration

Solar and wind farms benefit from the predictable performance of liquid cooling systems across varying environmental conditions. The wide operating temperature range (-40°C to 60°C) makes these systems suitable for extreme climates where air cooling would be inadequate.

Specialized Environments

The sealed nature of liquid cooling containers makes them ideal for challenging environments including:

- Coastal areas with high salt mist concentration;

- Desert regions with abundant fine sand and dust;

- High-humidity environments where condensation risks compromise electrical systems;

- Urban settings where space constraints and noise limitations exist.

Investment Value Proposition and ROI Analysis

For investors and project developers, liquid cooling containerized energy storage presents a compelling value proposition with demonstrable financial benefits:

Table 2: Economic Comparison of Liquid Cooling vs. Air Cooling Storage Systems

| Economic Factor | Liquid Cooling System | Air Cooling System | Financial Impact |

| Initial Investment Cost | $1.35/Wh | $1.33/Wh | 1.5% higher initial cost |

| Internal Rate of Return (IRR) | 15% (Zhejiang C&I project example) | 13% (Zhejiang C&I project example) | 15% higher IRR |

| Battery Life Expectancy | 20+ years | 10-15 years | 30-50% longer revenue period |

| Maintenance Cost | 30-40% lower | Standard | Significant long-term savings |

| Energy Density | 146 Wh/L | ~95 Wh/L | 50% more capacity per space unit |

| Installation Time | 50% reduction | Standard | Faster deployment and revenue generation |

| Temperature Management | Active liquid cooling | Passive air cooling | Reduced degradation, longer life |

Enhanced Investment Returns

Real-world project data from Zhejiang province demonstrates the superior financial performance of liquid cooling technology, with projects achieving 15% internal rate of return (IRR) compared to 13% for air-cooled alternatives. This 200-basis point advantage significantly enhances project viability and investor appeal.

Risk Mitigation

Liquid cooling systems offer investors important risk mitigation benefits through:

- Enhanced safety reducing fire risks and potential liability

- Proven technology with increasing deployment track record

- Longer warranty periods supported by extended expected service life

- Greater operational stability across diverse environmental conditions

Technology Development Trajectory and Future Trends

The evolution of liquid cooling technology continues at an accelerated pace, with several promising developments shaping the future of the industry:

Emerging Immersion Cooling Technology

The next frontier in thermal management for energy storage emerges with immersion cooling technology, which submerges battery cells directly in dielectric coolant. XING Mobility's IMMERSIO™ immersion cooling battery system represents this cutting-edge approach, capable of achieving 2P discharge rates (double the rated power output) and four times the output power of traditional air-cooled systems.

This technology demonstrates exceptional thermal runaway suppression, capable of reducing temperatures by thousands of degrees within 15 seconds of detection, effectively preventing fires and thermal spread.

Integration with Smart Energy Management

Future liquid cooling systems will increasingly incorporate AI-driven optimization platforms that enhance operational efficiency. Easyat Group's implementation features AI algorithms that optimize charge and discharge strategies, achieving 99% conversion efficiency and reducing operational costs by 40%.

Standardization and Scalability

The industry is moving toward standardized container designs that reduce engineering costs and deployment timelines. Ganfeng's "Fengheng One" approach enables rapid configuration of 100MWh power stations using standardized 6.25MWh modules, significantly simplifying large-scale project implementation.

Expert Q&A: Addressing Key Investor and Technical Questions

Q: How does liquid cooling technology impact the battery cycle life in real-world operating conditions?

A: Liquid cooling significantly extends battery cycle life by maintaining optimal operating temperatures and minimizing temperature variations between cells. Ganfeng's system achieves 15,000 charge-discharge cycles while maintaining over 80% of initial capacity, effectively doubling the service life compared to conventional air-cooled systems.

Q: What are the maintenance requirements for liquid cooling systems, and how do they compare to air cooling?

A: Liquid cooling systems require dramatically less maintenance than air-cooled alternatives, with 95% fewer rotating components that represent common failure points in traditional systems. The sealed nature of liquid cooling circuits means they require less frequent servicing than fan arrays in air-cooled systems.

Q: How does the total cost of ownership compare between liquid cooling and air cooling technologies over a 20-year period?

A: While liquid cooling systems command a small premium in initial investment (approximately 1.5%), they deliver significantly lower total cost of ownership over their operational lifetime. This advantage stems from longer service life (20+ years versus 10-15 years), reduced maintenance costs, higher energy efficiency, and better preservation of battery capacity over time.

Q: Are liquid cooling systems suitable for extreme climate conditions?

A: Yes, liquid cooling systems actually outperform air cooling solutions in extreme environments. Their sealed design provides protection against dust, sand, and corrosive salts, while their active thermal management maintains optimal operating temperatures in both extreme heat (-40°C to 60°C operating range) and cold conditions.

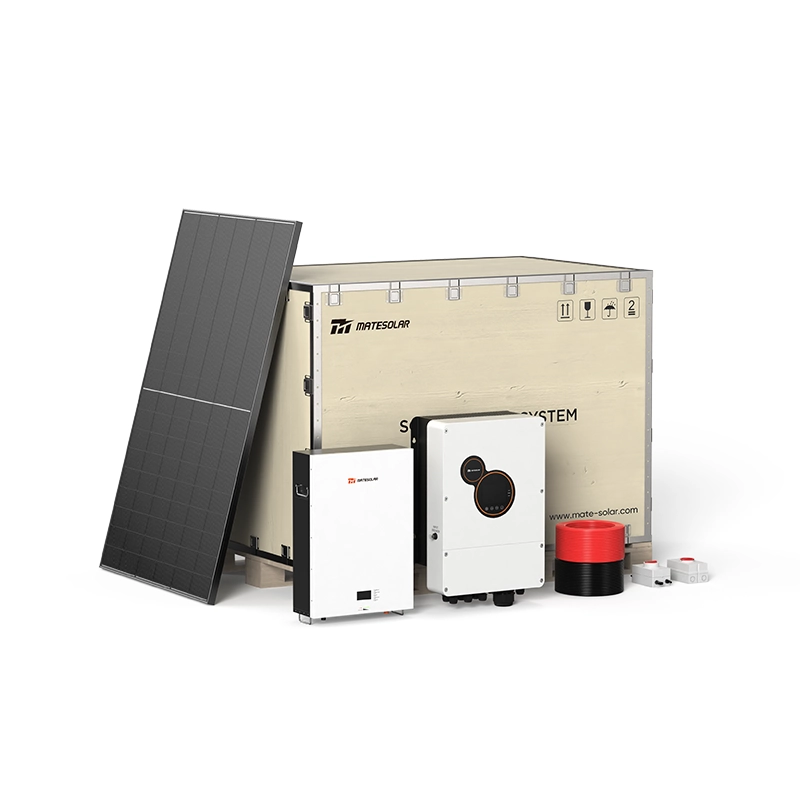

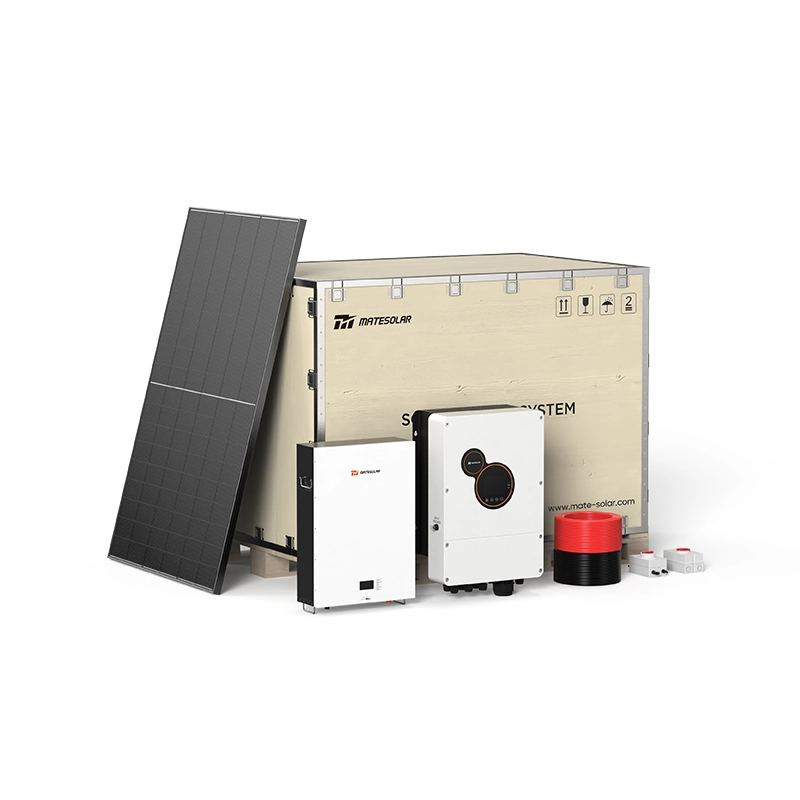

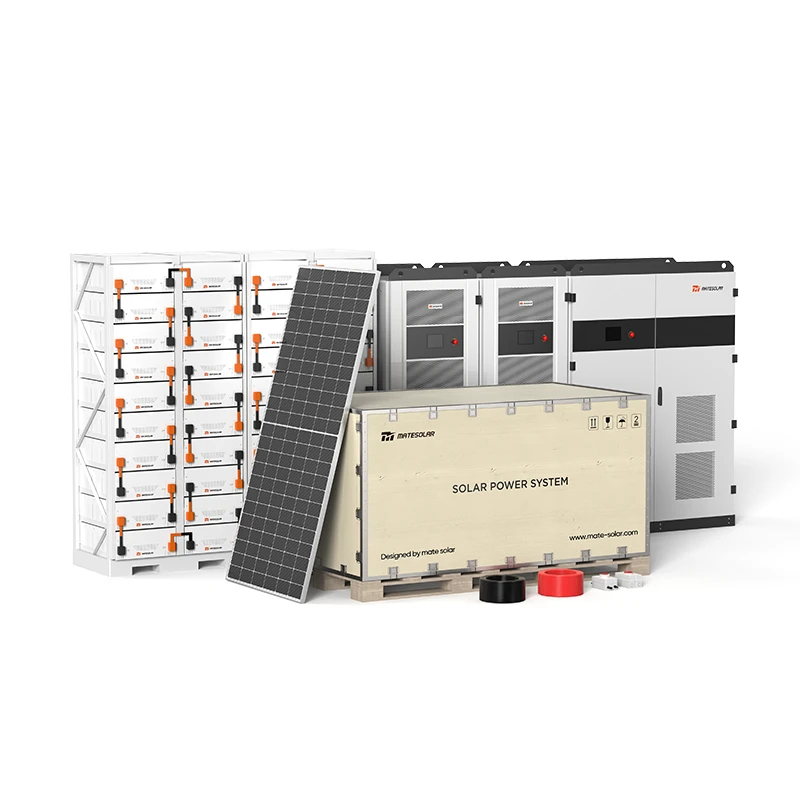

MateSolar: Integrating Advanced Liquid Cooling Technology Into Comprehensive Energy Solutions

As a leading provider of integrated photovoltaic storage solutions, MateSolar recognizes the transformative potential of liquid cooling containerized energy storage technology. Our approach combines these advanced storage systems with high-efficiency solar generation and intelligent energy management to deliver comprehensive solutions for commercial and industrial applications.

MateSolar's implementation of liquid cooling technology focuses on maximizing customer value through:

- Customized system design tailored to specific application requirements and environmental conditions

- Seamless integration with existing solar PV systems and energy infrastructure

- Advanced monitoring and control platforms that optimize system performance and ROI

- Comprehensive maintenance services that ensure long-term reliability and performance

The rapid adoption of liquid cooling technology represents a pivotal advancement in energy storage, addressing critical challenges of safety, efficiency, and longevity that have historically constrained broader deployment. For investors and project developers, these systems offer compelling financial advantages through enhanced performance, reduced maintenance costs, and extended service life.

As the energy storage industry continues to evolve, liquid cooling technology is poised to become the new standard for commercial and industrial applications, supported by demonstrated technical advantages and proven economic benefits. MateSolar remains at the forefront of this technological transition, integrating the latest advances in thermal management into our comprehensive energy solutions to deliver superior value for our customers.