How AI, Predictive Maintenance, and Operational Strategies Transform Storage Systems from Cost Centers to Profit Drivers

The global transition to renewable energy has positioned energy storage systems (ESS) as critical components of grid stability and energy independence. However, the promise of storage—balancing supply-demand gaps and enabling higher renewable penetration—is undermined by premature battery degradation, inefficient maintenance, and unplanned costs. While the industry has mastered building affordable storage, the real challenge lies in managing it effectively over its lifespan. This article explores how a scientific, full-lifecycle approach bridges the gap between "building cheap" and "operating smart," ensuring reliability, profitability, and sustainability.

1. The Core Challenge: Why Storage Systems Underperform

Despite manufacturers touting cycle lives of 10,000–15,000 cycles (equivalent to 20–25 years), real-world data reveals a stark contrast:

- Early Retirement: Power-type ESS, promised to last 10 years, often retire within 3 years; energy-type ESS, rated for 20 years, frequently degrade within 3–5 years.

- Performance Gaps: Annual cycle counts rarely exceed 50% of design specifications, while inconsistent temperatures and improper charging accelerate capacity fade.

- Systemic Weaknesses: Non-battery components (e.g., cooling systems, power conversion systems) often fail to match the battery’s lifespan. For example, coolant fluids require replacement every 2–5 years, and IGBT modules in PCS act as "consumables" needing frequent maintenance.

*Table 1: Real-World vs. Designed ESS Lifespan*

| Component | Claimed Lifespan | Actual Lifespan | Key Failure Causes |

| Power-type ESS | 10 years | <3 years | Thermal stress, poor BMS calibration |

| Energy-type ESS | 20 years | 3–5 years | Lithium loss, coolant degradation |

| Coolant Systems | 2–5 years | Requires periodic replacement | Fluid acidification, clogging |

| PCS IGBT Modules | 10–15 years | 3–7 years | High-temperature cycling |

2. Pillars of Lifecycle Management: Technology & Strategy

2.1 Intelligent Monitoring: The Role of AI and Big Data

Traditional monitoring systems react to failures; AI-driven platforms predict and prevent them. Examples include:

- Battery Digital Brain: Developed by Dalian Institute of Chemical Physics, this system uses multi-layered AI algorithms to forecast failures days in advance, elevating warning times from minutes to days.

- Cloud-Based ML Diagnostics: Aggregating data from large fleets, machine learning models adapt to diverse chemistries and usage patterns, improving SOH (State of Health) and RUL (Remaining Useful Life) predictions.

- Integrated Platforms: CET’s centralized OM platform synchronizes data from distributed PV, wind, and ESS sites, enabling real-time diagnostics and maintenance scheduling.

2.2 Health Management Strategies

Charging Optimization:

- Shallow Charge-Discharge: Avoiding deep cycles reduces lithium consumption. Hithium’s "active lithium slow-release" technology balances lithium supply with demand, extending cycle life.

- Active Balancing: HiTHIUM’s embedded equalization devices maintain cell voltage consistency without system shutdowns, cutting downtime by 11 hours.

Thermal Management:

- Temperature fluctuations are a primary degradation driver. Every 15°C rise above 25°C halves battery life. Solutions include:

- Liquid Cooling: HiTHIUM’s design boosts lifespan by 20% but requires fluid changes every 2–5 years. Newer designs, like Tongfei’s long-life coolant, aim for 5+ years without replacement.

- High-Temperature Tolerance: CATL’s cells operate at >35°C without cooling, reducing dependency on thermal systems.

Current Rate Control:

- High C-rates (>1C) induce mechanical stress. Limiting currents to ≤0.5C improves cycle life by 40%.

Table 2: Health Management Impact on Lifespan

| Strategy | Implementation | Lifespan Gain |

| Shallow Cycling | 20–80% SOC operation | +30% |

| Active Balancing | Real-time voltage correction | +15% |

| Precision Cooling | Maintain 25±2°C | +100% (per 10°C reduction) |

| C-Rate Limiting | Charge/discharge ≤0.5C | +40% |

2.3 Economic Analysis: The Business Case for Lifecycle Management

Storage projects must justify costs through long-term returns:

- Cost Breakdown:

- Initial investment: 40–50%

- O&M: 20–30%

- Recycling value: 5–10%

- ROI of Longevity: Extending battery life from 6 to 10 years reduces levelized storage costs by 30%, boosting IRR by 2–3 percentage points. HiTHIUM’s 15,000-cycle battery, for example, enables 27-year system life

- O&M Savings: Predictive maintenance slashes unplanned downtime by 30%, while centralized platforms reduce labor costs

3 Implementing Lifecycle Management: A Step-by-Step Guide

3.1 Planning and Design

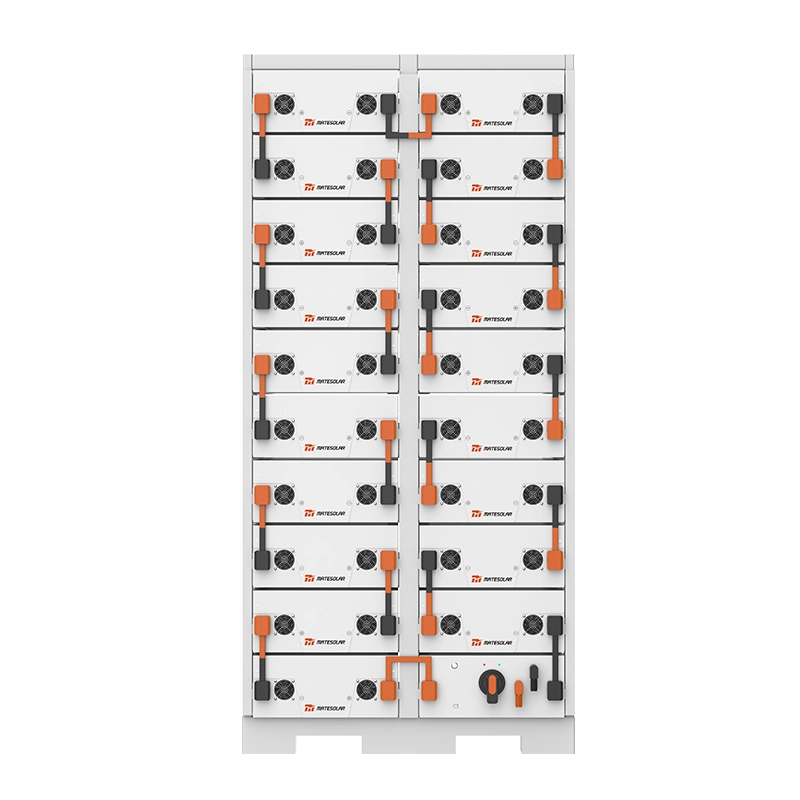

- Scalability: Huawei’s "building-block" ESS supports online capacity expansion.

- Standardization: Use universal communication protocols (e.g., CAN, Modbus) to ensure component interoperability.

3.2 Operational Maintenance

- Three-Tier Monitoring: Combine cloud analytics (e.g., CET’s platform), local controllers, and device-level self-checks for 24/7 oversight

- Proactive Alerts: Set thresholds for SOC, SOH, temperature, and internal resistance. HiTHIUM’s BMS achieves SIL2 safety certification with failure rates <1/100,000 hours

- Scheduled Maintenance: Quarterly health checks and annual full-system tests identify underperforming cells early.

3.3 Second Life and Recycling

- Echelon Reuse: At SOH <80%, repurpose batteries for less demanding applications (e.g., backup power, low-speed EVs), adding 15–20% post-retirement value.

- Formal Recycling: Partner with certified recyclers for material recovery. Regulatory frameworks like China’s "New Energy Vehicle Power Battery Recycling Management Measures" subsidize compliant processes.

4 FAQs

1. How do cycle counts translate to actual lifespan?

A: If a system completes 1 cycle daily, 15,000 cycles equal ~41 years. However, real-world factors like temperature and C-rates often reduce this by 30–50%.

2. Why is temperature control so critical?

A: Battery longevity halves with every 15°C increase above 25°C. Precision cooling (e.g., liquid systems) is essential for maximizing cycle life.

3. What distinguishes AI-driven BMS from conventional systems?

A: Traditional BMS react to anomalies; AI models (e.g., Dalian’s "digital brain") predict failures days ahead and optimize charging in real-time.

4. Can storage systems truly match PV system lifespans (25+ years)?

A: Yes, but only with robust lifecycle management. While batteries like HiTHIUM’s support 27-year lifespans, components like PCS and coolers require upgrades or maintenance.

5. How are retired batteries managed sustainably?

A: Through echelon reuse (e.g., solar street lighting) and formal recycling, recovering materials like lithium and cobalt.

The evolution from "building affordable storage" to "managing it optimally" demands a holistic lifecycle approach—blending AI monitoring, proactive maintenance, and circular economy principles. By prioritizing longevity over lowest upfront costs, developers and operators can unlock decades of reliable, profitable performance.

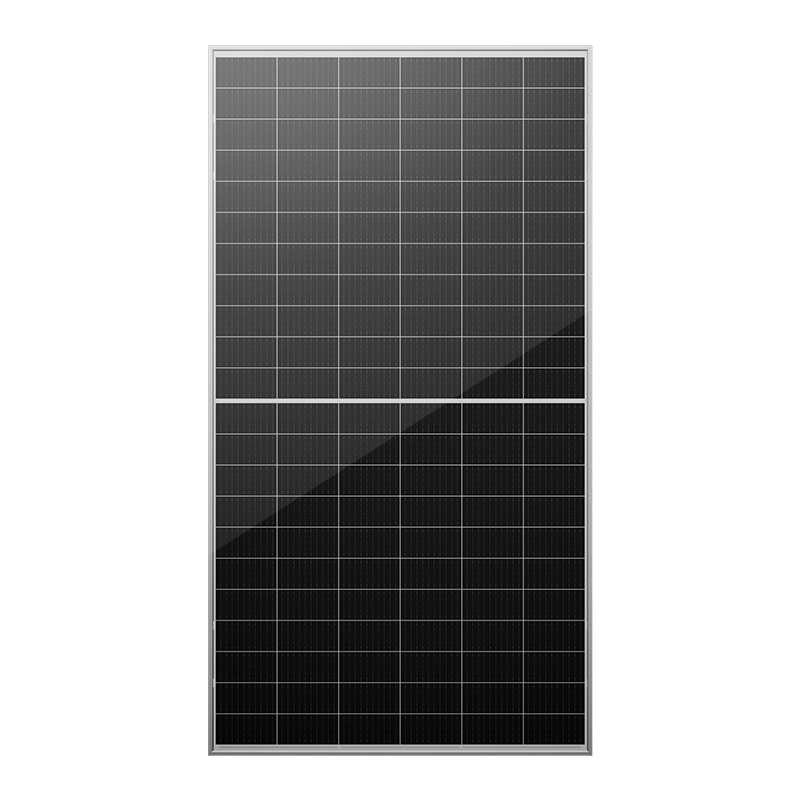

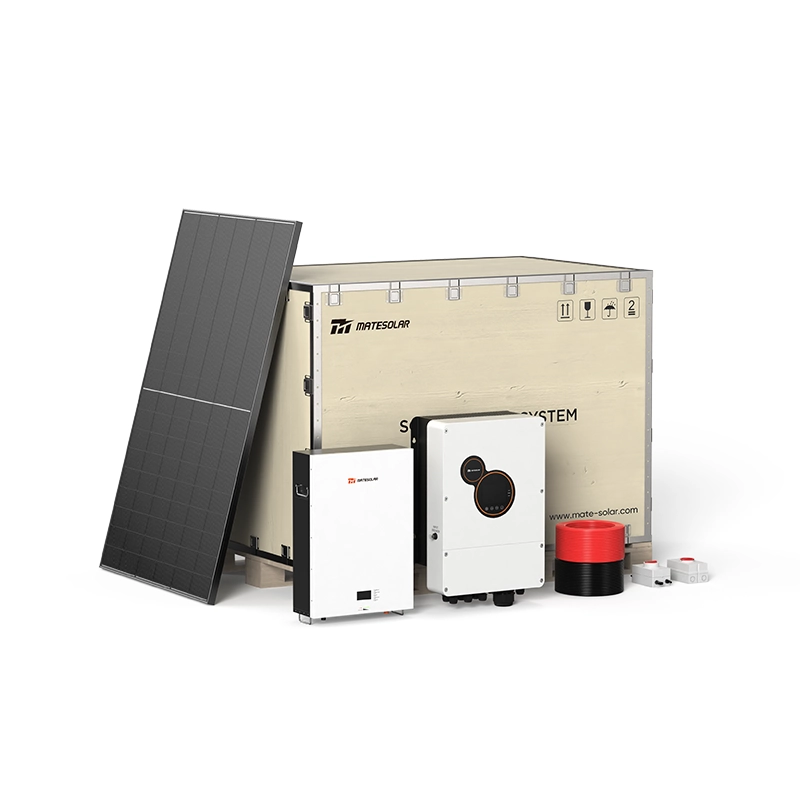

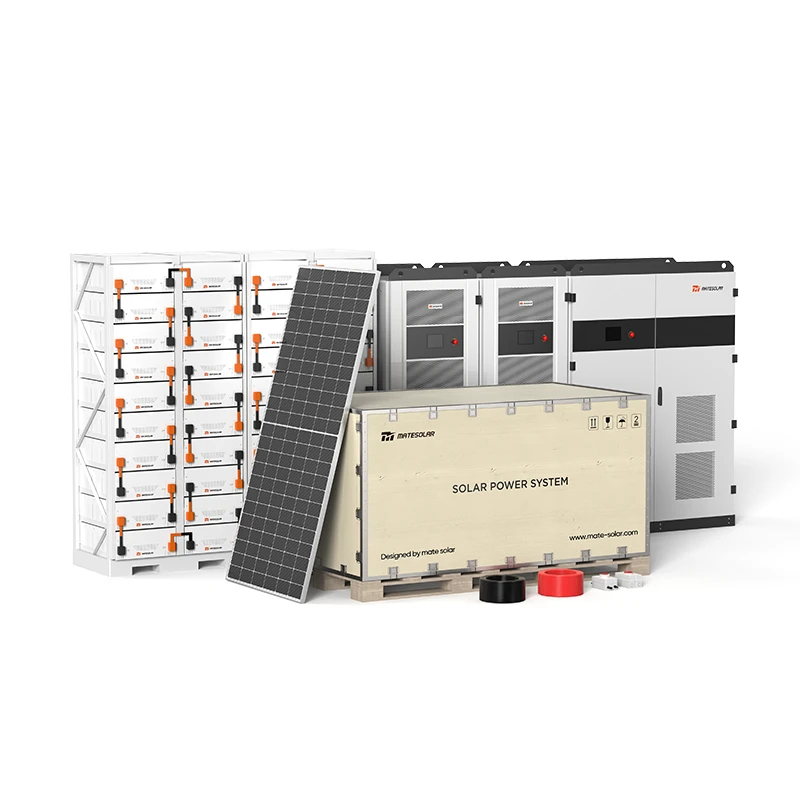

MateSolar delivers end-to-end photovoltaic and energy storage solutions, integrating premium components with intelligent lifecycle management to maximize sustainability and returns. Explore our Solar PV Energy Storage Systems for utility-scale projects or the 100KW Hybrid Solar System

for high-efficiency home applications.

Take the first step toward energy independence—contact MateSolar today for a personalized commercial energy storage assessment!