The rapid expansion of renewable energy integration has created unprecedented demand for robust energy storage solutions capable of operating in diverse environmental conditions. Air-cooled containerized energy storage systems have emerged as a critical technology for industrial and commercial applications, particularly in challenging environments where reliability, maintainability, and thermal management are paramount. These systems represent a sophisticated convergence of thermal engineering, battery technology, and intelligent control systems designed to deliver unprecedented performance across extreme operating conditions.

Technical Architecture & Design Innovations

Modern air-cooled containerized systems incorporate multiple technological advancements that differentiate them from conventional solutions. The architectural framework typically consists of:

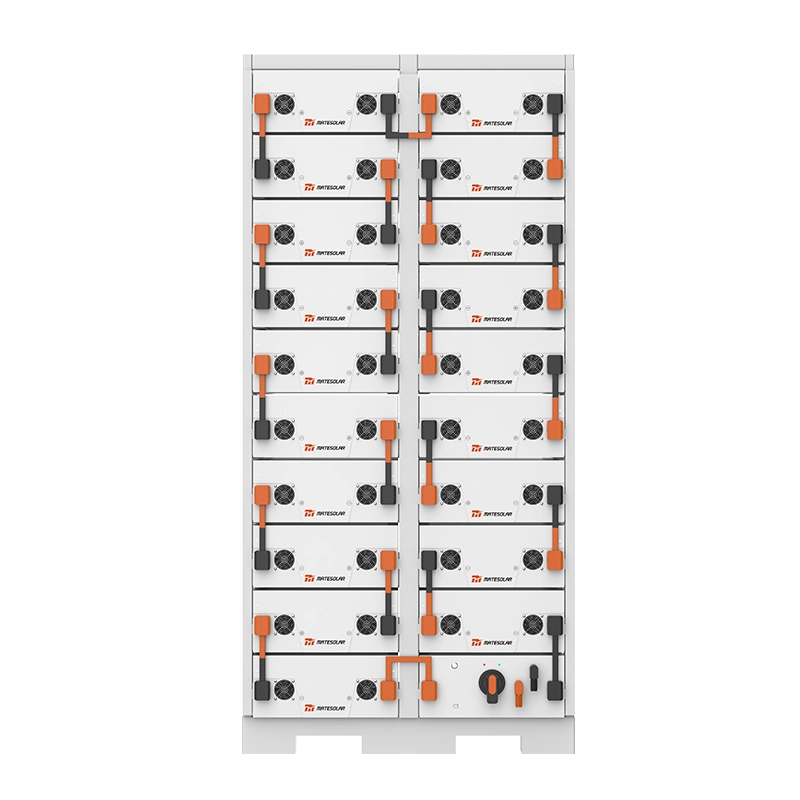

Modular Battery Compartments: Segmented energy storage units with independent thermal management and safety systems, enabling precise environmental control and enhanced safety through compartmentalization.

Intelligent Airflow Management: Advanced computational fluid dynamics (CFD)-optimized airflow pathways ensure uniform temperature distribution across all battery modules, maintaining cell-to-cell temperature differentials below 3°C even during rapid charging/discharging cycles.

Multi-Zone Climate Control: Sophisticated temperature zoning allows different sections of the container to operate at optimal temperatures based on specific battery chemistry requirements and operational status.

Table 1: Performance Comparison of Cooling Technologies

| Parameter | Air-Cooled Systems | Liquid-Cooled Systems | Hybrid Systems |

| Temperature Uniformity | ≤3°C differential | ≤2°C differential | ≤1.5°C differential |

| Energy Efficiency | 92-95% | 88-92% | 94-96% |

| Maintenance Complexity | Low | High | Medium |

| Installation Cost ($/kWh) | $120-150 | $180-220 | $160-200 |

| Operating Cost ($/kWh/year) | $4-6 | $7-9 | $5-7 |

| Environmental Adaptability | Excellent | Good | Excellent |

| System Lifespan (years) | 15+ | 12-15 | 15+ |

| Altitude Tolerance (meters) | 3,500+ | 2,500 | 4,000+ |

Extreme Environment Performance Metrics

Air-cooled containerized systems demonstrate exceptional performance across diverse challenging conditions:

High-Temperature Environments: Systems maintain operational integrity at ambient temperatures up to 50°C through advanced multi-stage cooling technology, with thermal runaway prevention mechanisms capable of containing single-cell thermal events without propagation.

Low-Temperature Operation: Specialized heating systems enable operation down to -40°C, with rapid cold-start capabilities achieving full operational status within 15 minutes at -30°C.

High-Altitude Applications: Reduced atmospheric density compensation technology maintains cooling efficiency at altitudes exceeding 3,500 meters, with specialized components rated for thin-air operation.

Corrosive Environments: Marine-grade stainless steel construction and specialized coating systems provide protection against salt spray, achieving C5-M corrosion resistance classification.

Table 2: Environmental Performance Specifications

| Environmental Factor | Performance Standard | Test Methodology | Industry Benchmark |

| High Temperature | 50°C continuous operation | IEC 60068-2-2 | 45°C |

| Low Temperature | -40°C with heating system | IEC 60068-2-1 | -30°C |

| Altitude | 4,000 meters operational | IEC 60068-2-13 | 2,000 meters |

| Humidity | 95% RH non-condensing | IEC 60068-2-78 | 85% RH |

| Seismic Resistance | Seismic Zone 4 compliance | IEC 60068-3-3 | Zone 3 |

| Ingress Protection | IP54 minimum (IP66 available) | IEC 60529 | IP51 |

| Corrosion Resistance | C5-M classification | ISO 12944-6 | C4 |

Advanced Thermal Management Systems

The heart of modern air-cooled systems lies in their sophisticated thermal management approaches:

Predictive Cooling Technology: AI-driven algorithms analyze weather forecasts, usage patterns, and battery health data to pre-cool systems before anticipated thermal loads, reducing peak cooling demands by up to 40%.

Phase Change Materials (PCM) Integration: Strategic placement of PCM units provides thermal buffering during cooling system transitions or peak load events, enhancing system stability and reducing compressor cycling.

Variable Speed Architecture: Intelligent fan and compressor control matches cooling output precisely to thermal requirements, reducing auxiliary power consumption by 30-40% compared to fixed-speed systems.

Redundant Cooling Paths: Multiple independent cooling circuits ensure continued operation during maintenance or component failure, with automatic failover capabilities.

Technical Q&A: Addressing Critical Engineering Considerations

Q: How do modern air-cooled systems achieve temperature uniformity comparable to liquid cooling?

A: Advanced systems utilize CFD-optimized airflow management with variable-speed fans that dynamically adjust to thermal loads. Multi-zone temperature monitoring with real-time airflow adjustment ensures temperature differentials remain below 3°C. Additionally, thermal interface materials with high conductivity enhance heat transfer from cells to cooling air streams.

Q: What safety enhancements are specific to air-cooled containerized systems?

A: These systems incorporate multi-level safety protocols including: 1) Pack-level isolation systems that contain thermal events within individual modules; 2) Advanced gas detection and ventilation systems that maintain safe atmospheric conditions; 3) Fire suppression systems specifically designed for lithium-ion batteries; 4) Emergency cooling modes that activate during abnormal thermal conditions.

Q: How does the total cost of ownership compare between air-cooled and liquid-cooled systems?

A: While initial installation costs favor air-cooled systems by 20-30%, the operational cost advantage is more significant. Air-cooled systems typically show 30-40% lower maintenance costs, 25-35% reduced auxiliary power consumption, and simpler service requirements. The lifetime cost per kWh stored can be 15-25% lower for air-cooled systems in appropriate applications.

Q: What battery chemistries are best suited for air-cooled containerized systems?

A: While most modern lithium-ion chemistries perform well, LFP (Lithium Iron Phosphate) batteries are particularly well-suited due to their superior thermal stability, wider temperature tolerance, and lower cooling requirements. Advanced systems can also accommodate NMC chemistries with appropriate thermal management adjustments.

Q: How are these systems adapting to evolving regulatory requirements?

A: Modern systems incorporate: 1) Enhanced safety systems exceeding current regulatory standards; 2) Remote monitoring and reporting capabilities for compliance documentation; 3) Modular designs that allow upgrades to meet future requirements; 4) Environmental containment systems that prevent any material release under fault conditions.

Economic & Operational Advantages

The implementation of advanced air-cooled containerized systems delivers significant economic benefits:

Reduced Capital Expenditure: Simplified infrastructure requirements and standardized components lower initial investment by 20-30% compared to liquid-cooled alternatives.

Operational Efficiency: Higher system efficiency (92-95% round-trip efficiency) translates to greater energy availability and reduced operating costs.

Maintenance Optimization: Modular design enables rapid component replacement and reduces mean time to repair (MTTR) by up to 60% compared to complex liquid-cooled systems.

Scalability: Containerized approach allows incremental capacity expansion with minimal disruption to existing operations.

Table 3: Financial Analysis (10-Year Horizon)

| Financial Metric | Air-Cooled System | Liquid-Cooled System | Advantage |

| Initial Investment ($/kWh) | $140-160 | $180-220 | 22% reduction |

| Annual Maintenance ($/kWh) | $4.50-5.50 | $7.00-8.50 | 35% reduction |

| Energy Loss Cost ($/kWh/year) | $0.85-1.05 | $1.20-1.50 | 29% reduction |

| System Availability | 99.2% | 98.5% | 0.7% improvement |

| Total Cost of Ownership | $210-230/kWh | $260-300/kWh | 19% reduction |

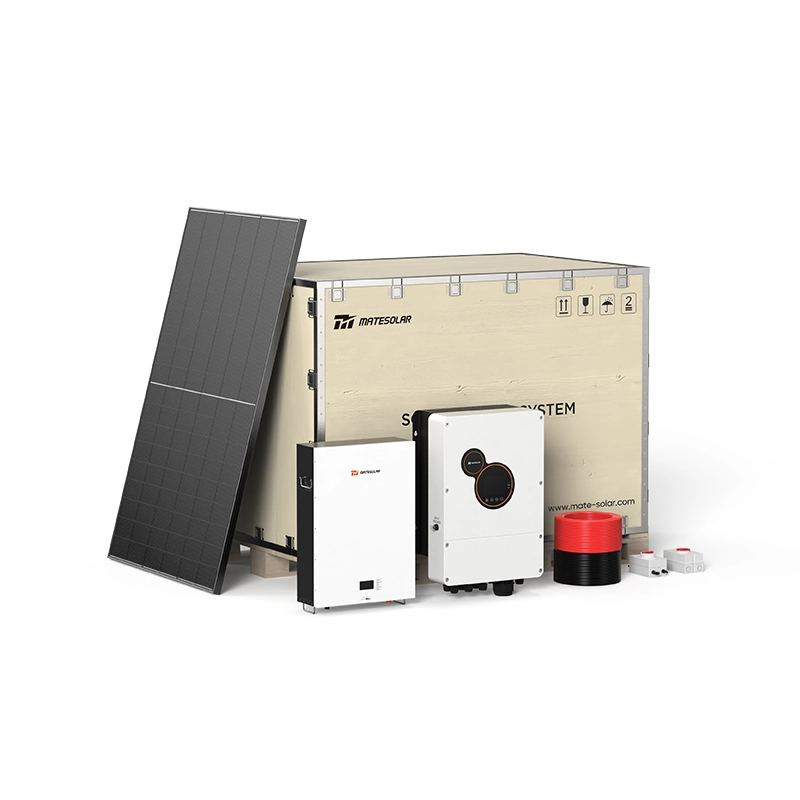

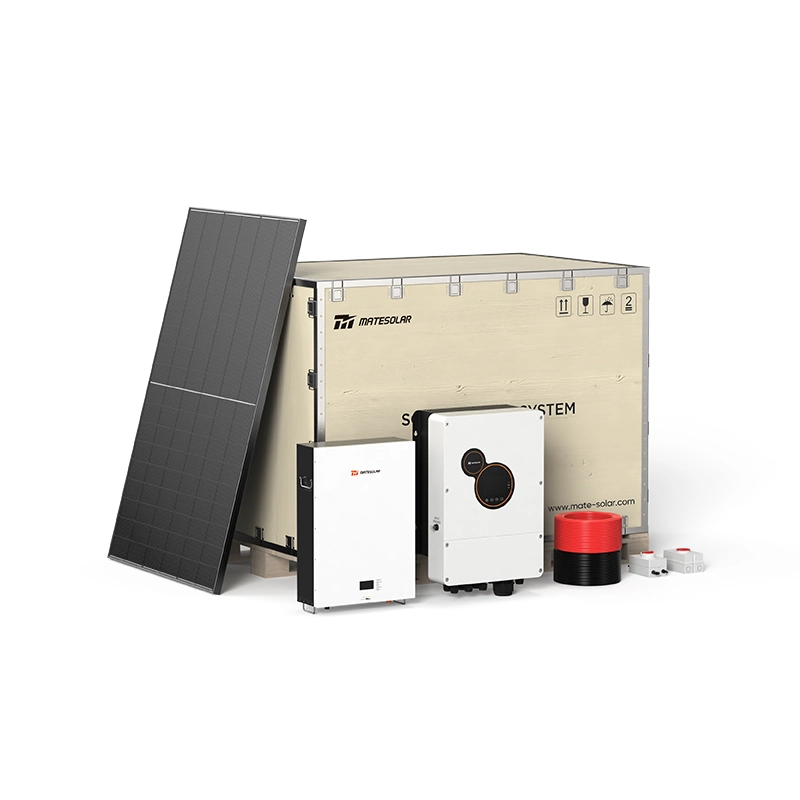

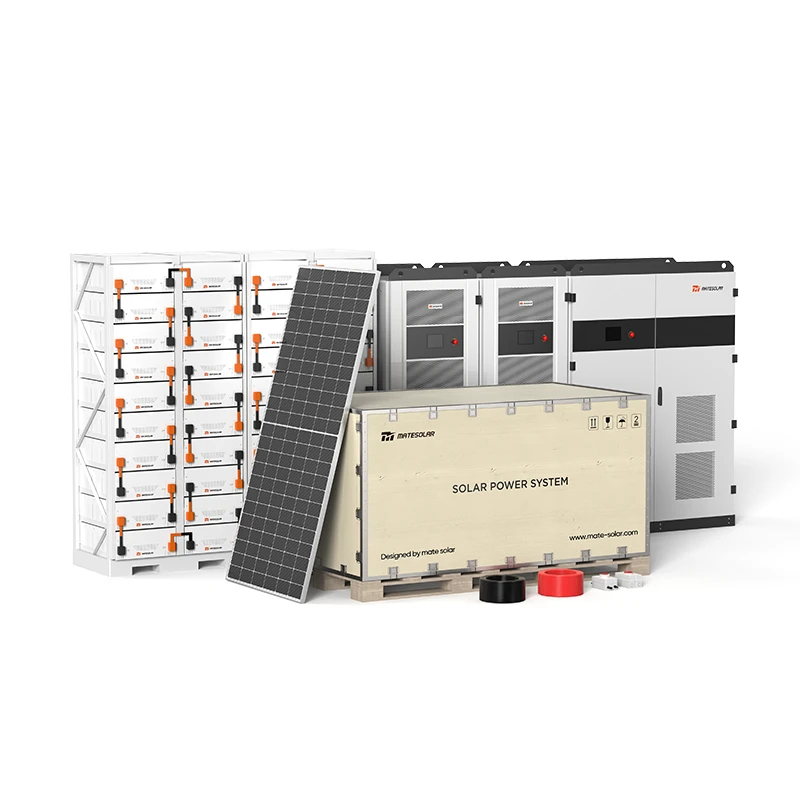

MateSolar Engineering Excellence

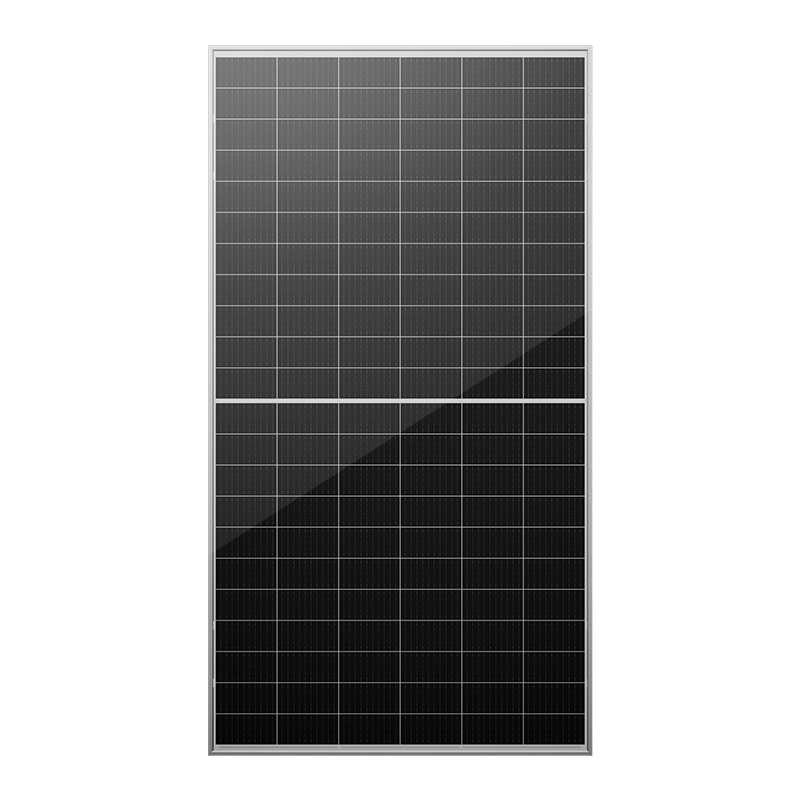

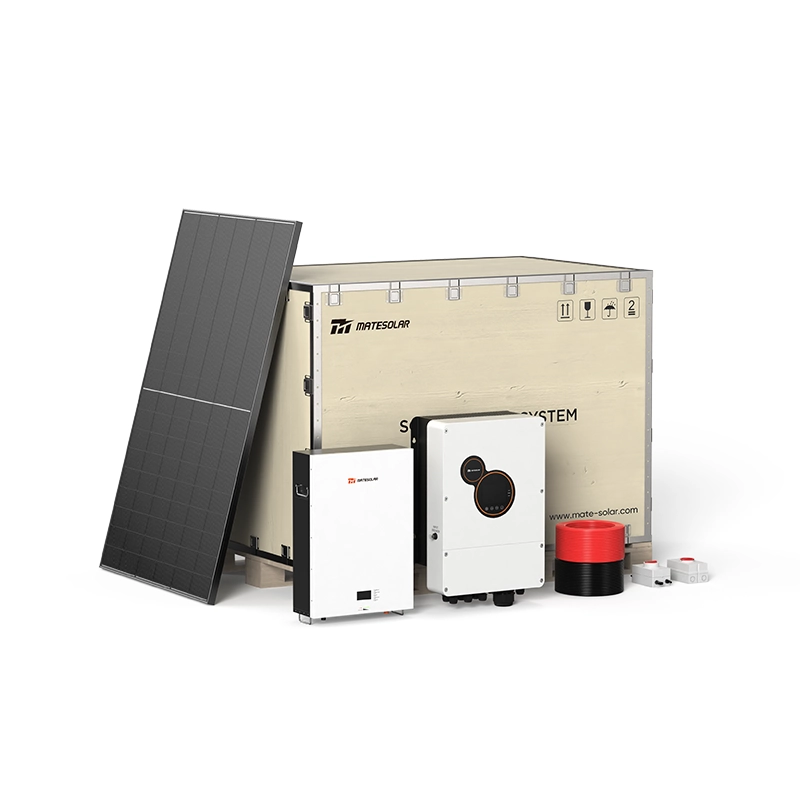

MateSolar has pioneered advanced air-cooled containerized energy storage solutions that redefine reliability in extreme environments. Our systems incorporate proprietary thermal management technology that ensures optimal performance across the broadest range of environmental conditions in the industry.

The MateSolar advantage includes:

Adaptive Cooling Architecture™: Our patented variable-flow cooling system dynamically adjusts to environmental conditions and load requirements, maintaining optimal temperatures with minimal energy consumption.

Quantum Battery Management System: Advanced algorithms continuously optimize performance, safety, and longevity based on real-time analysis of battery health and environmental factors.

Extreme Environment Package: Specialized options for specific environmental challenges including Arctic operation packages, tropical climate systems, and high-altitude configurations.

Integrated Solar Optimization: Native integration with photovoltaic systems enables seamless energy harvesting, storage, and dispatch tailored to specific operational requirements.

As a leading provider of integrated photovoltaic storage solutions, MateSolar delivers comprehensive energy resilience for commercial and industrial applications worldwide. Our containerized energy storage systems represent the culmination of decades of engineering innovation, providing reliable power solutions for the most demanding applications and environments.

About MateSolar: MateSolar delivers advanced integrated energy storage solutions for commercial and industrial applications worldwide. Our containerized energy storage systems combine cutting-edge thermal management technology with sophisticated control systems to provide reliable performance in even the most challenging environmental conditions. With deployments across six continents and expertise spanning decades, MateSolar is the preferred partner for organizations seeking to enhance their energy resilience and sustainability.