Facing unprecedented AI-driven demand and a shifting policy landscape, U.S. data centers and high-end commercial & industrial (C&I) operators must redefine their energy strategy. This guide details how a partner-centric, solutions-based approach—combining compliant technology with strategic deployment—is key to securing reliability, speed, and financial viability.

The U.S. power sector is at a historic inflection point. Where electricity demand remained nearly flat for decades, forecasts now predict a nationwide surge of 15.8% over the next five years, driven overwhelmingly by the exponential growth of artificial intelligence (AI) and data centers. In regions like Virginia and Georgia, utilities have revised load growth forecasts upward by tens of percentage points in a single year.

Simultaneously, the enactment of the One Big Beautiful Bill Act (OBBBA) has dramatically reshaped the regulatory and economic playing field for renewable energy. For project developers, investors, and operators, success now hinges on navigating a dual challenge: securing massive, reliable power for AI workloads while adhering to stringent new compliance rules.

This article provides a comprehensive roadmap for turning these challenges into competitive advantage, emphasizing that the right partner delivers not just equipment, but a de-risked, accelerated path to project completion.

Part 1: The New American Energy Reality: OBBBA & The AI Power Crunch

The convergence of transformative policy and explosive demand creates both urgency and opportunity.

1.1 The OBBBA Era: Reshaped Incentives and the "Compliance Imperative"

The OBBBA marks a fundamental policy shift, moving away from broad clean energy support to a more strategic, domestically-focused framework. Understanding its nuances is critical for project economics.

- A Divergent Path for Solar and Storage: The act accelerates the phase-out of key investment tax credits (ITC) for standalone solar and wind projects, moving deadlines from 2032 to as early as 2026-2027. However, in a crucial distinction, standalone and renewable-paired storage projects have seen their ITC support extended to 2036. This creates a powerful incentive to pair storage with generation, making integrated solar-plus-storage projects more financially attractive than standalone solar.

- The "Foreign Entity of Concern" (FEOC) Hurdle: Perhaps the most significant operational challenge is the strict limitation on materials and components from FEOCs, a category that includes entities tied to specific nations like China. To qualify for the remaining ITC benefits, projects must ensure their battery cells, modules, and critical minerals comply with evolving FEOC rules. This necessitates deep supply chain transparency and vetting capabilities from any technology partner.

- Strategic Funding Shifts: The OBBBA reallocates funding toward grid reliability, long-duration storage demonstration projects, and infrastructure upgrades. This highlights a national priority for resilient, dispatchable power—a core function of modern energy storage systems (ESS).

1.2 The AI Data Center Power Crisis: Reliability at Scale

AI data centers are not merely large loads; they are constant, high-density, and mission-critical. A single hyperscale campus can require hundreds of megawatts, comparable to a mid-sized city. The traditional grid is struggling to keep pace.

- The Interconnection Queue Bottleneck: Securing a grid interconnection for new generation can take nearly five years, with new transmission lines taking eight years or more. This timeline is untenable for AI companies racing to deploy capacity.

- The "Behind-the-Meter" Solution Surge: To bypass grid delays, major operators are increasingly turning to "behind-the-meter" (BTM) power solutions. These involve developing dedicated generation and storage resources directly on-site or adjacent to the load, creating a more controlled and rapidly deployable power ecosystem. Projects like the planned 11 GW "Project Matador" in Texas exemplify this trend.

- The "Power Couple" Advantage: Research from RMI highlights an effective model: co-locating new data center loads with new-build solar, wind, and battery storage near existing grid interconnection points. This "Power Couple" strategy can fast-track approval, shield the broader grid from reliability risks, and deliver over 50 GW of capacity with high percentages of clean energy.

Part 2: The 3C Solution Framework: Compliance, Reliability, and Speed

Succeeding in this environment requires a solution built on three pillars. It’s no longer about buying components, but about implementing a strategic energy asset.

2.1 Pillar 1: Compliance by Design

Navigating OBBBA and FEOC rules requires proactive, integrated planning.

- Supply Chain Architecture: Partners must provide verifiable, document-backed supply chains for battery cells and components that meet FEOC requirements. This often involves leveraging non-FEOC aligned LFP (Lithium Iron Phosphate) cell production and U.S.-based system integration.

- Certification and Documentation: Full compliance for interconnection and incentives demands rigorous certification. Systems must carry relevant U.S. and international standards such as UL 9540, UL 1973, IEEE 1547, and NEC compliance. The partner’s role is to manage this complex certification portfolio, ensuring the system is "audit-ready."

- ITC Optimization Strategy: A knowledgeable partner will design the system to maximize the available 30%+ ITC for storage, ensuring all eligibility criteria for cost-basis calculations are met and properly documented.

2.2 Pillar 2: Engineered for Mission-Critical Reliability

Data centers demand 99.999% (or higher) uptime. Their energy infrastructure must be equally resilient.

- Technology Selection: LFP battery chemistry has become the industry standard for C&I and data center applications due to its superior safety profile, long cycle life (often exceeding 6,000 cycles), and thermal stability.

- Advanced System Design: Reliability is engineered at the system level. This includes:

- Precision Thermal Management: Liquid-cooling or advanced forced-air cooling systems maintain optimal cell temperature, preventing degradation and ensuring performance in extreme climates.

- Cybersecurity Hardened Communications: Secure, redundant protocols (e.g., IEC 61850, Modbus TCP) for grid interaction and remote management.

- Grid-Forming Inverter Capability: The most advanced systems can "form" a grid independently, providing black-start capability and stabilizing the local microgrid.

- Performance Guarantees: Trust is built on transparent warranties guaranteeing throughput, capacity retention over time, and system availability.

2.3 Pillar 3: Accelerated Deployment and Scalability

Time-to-power is a critical competitive metric. Speed is achieved through modularization and expert execution.

- Containerized, Plug-and-Play Architecture: The use of pre-engineered, containerized energy storage systems is transformative. These 20ft or 40ft units arrive site-ready, with batteries, BMS, PCS, cooling, and fire suppression fully integrated and tested in the factory. This slashes field installation time and complexity by up to 70% compared to stick-built solutions.

- Phased and Scalable Deployment: A modular containerized approach allows capacity to be deployed in phases, aligning with data center build-out or load growth. Additional power (PCS) or energy (battery) containers can be added seamlessly.

- Streamlined Interconnection Support: Experienced partners provide comprehensive interconnection support—from application engineering and studies to managing utility relationships—navigating the process far more efficiently than an owner could alone.

Part 3: Solution Architectures for Target Applications

The optimal system configuration varies by use case and scale. Below is a comparison of scalable solutions.

| Use Case & Scale | Primary Challenge | Recommended Solution Architecture | Key Features & Benefits |

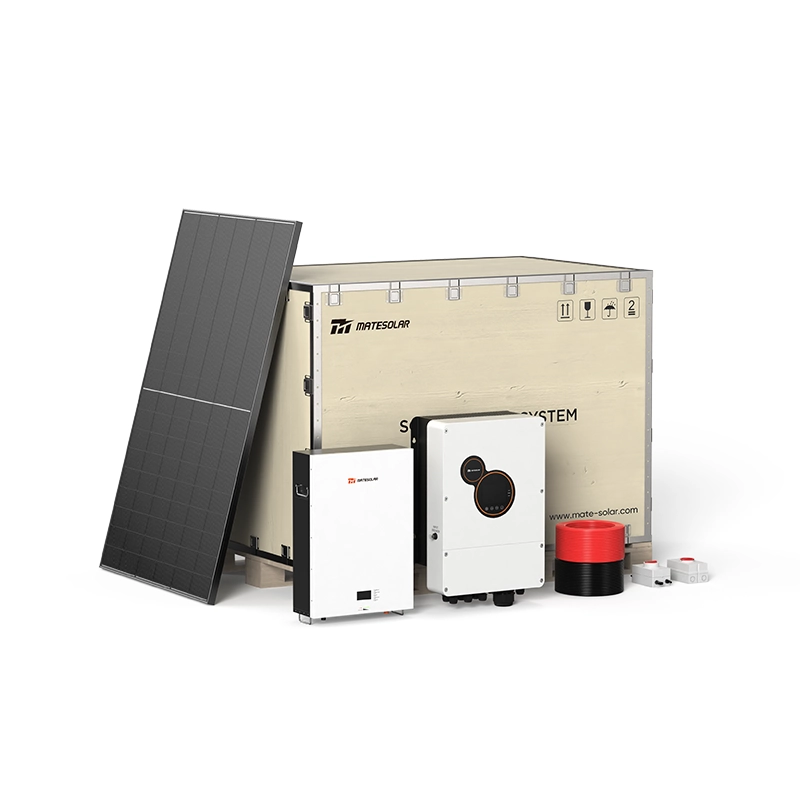

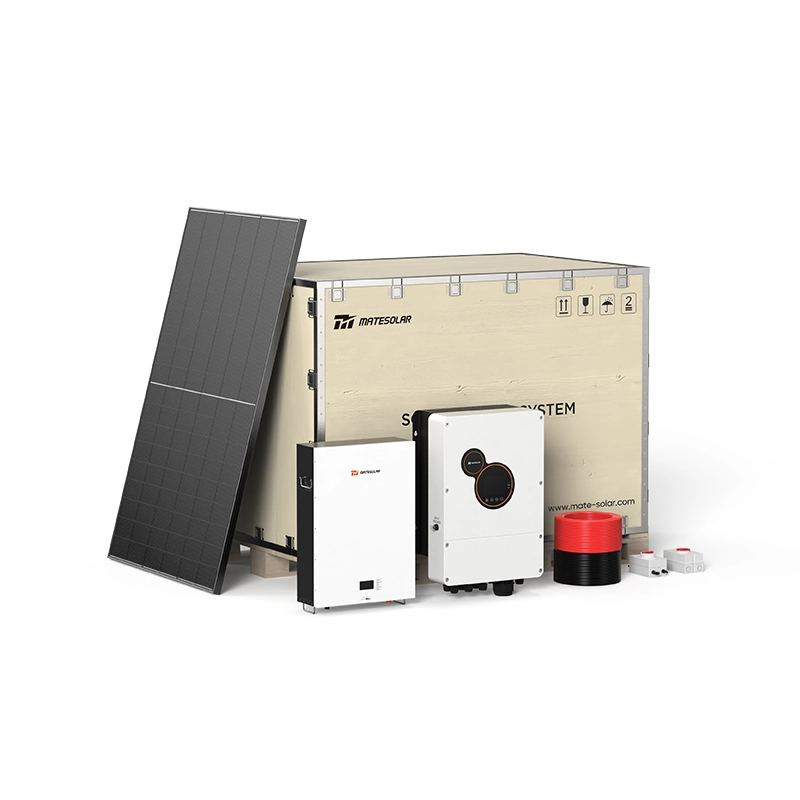

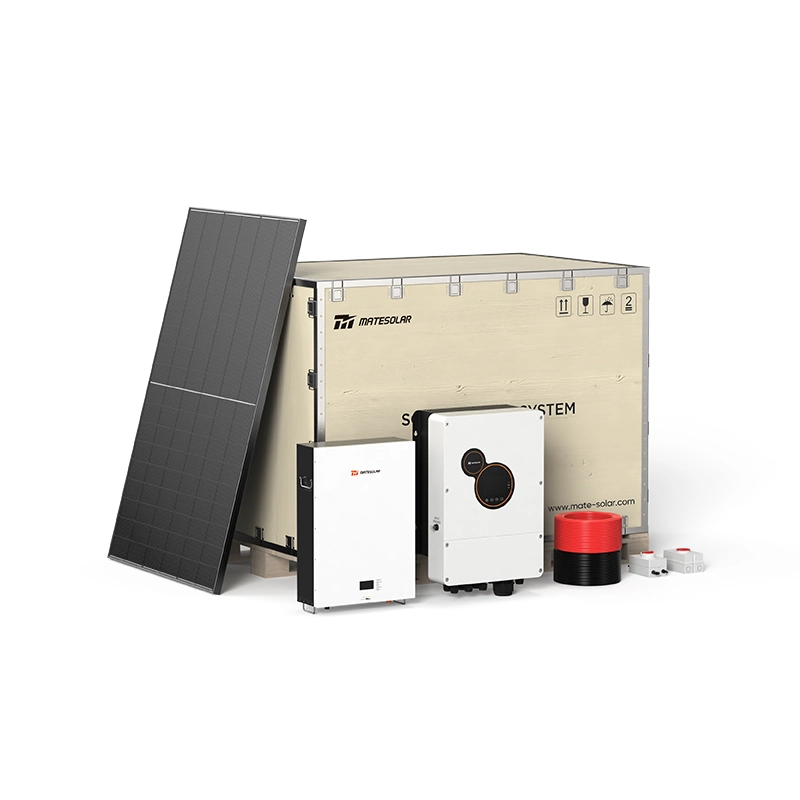

| Medium C&I / IT Loads (e.g., Office Parks, Manufacturing, Edge Data Centers) | High demand charges, grid reliability, limited space. | Integrated Hybrid Solar + Storage System (e.g., 250kW scale). A unified system combining solar generation with built-in storage. | Maximizes self-consumption of solar, reduces peak demand charges, provides backup power. Compact, all-in-one design simplifies permitting and installation. Explore our standardized Commercial 250KW Hybrid Solar System for a proven, efficient solution. |

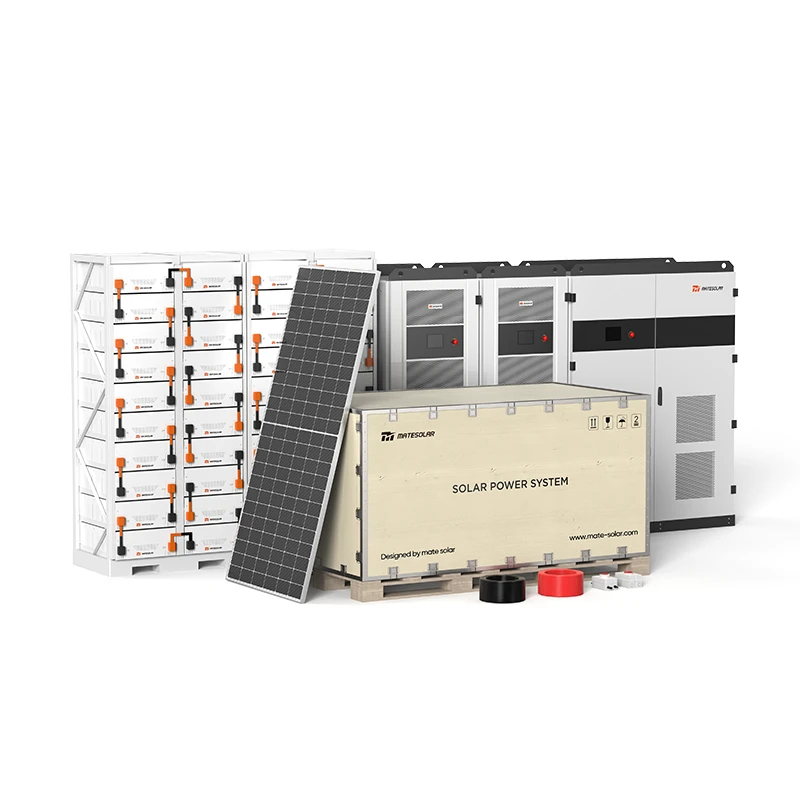

| Large C&I / AI Data Halls (Multiple MW scale) | Meeting massive, constant load; bypassing grid delays; achieving clean energy goals. | "Power Couple" Model: Dedicated Solar Farm + Containerized ESS. A behind-the-meter microgrid pairing ground-mounted solar with multi-MWh containerized battery storage. | Rapid deployment via pre-fab containers. Decouples load from grid constraints. Enables high percentage of 24/7 clean energy. Provides grid services revenue potential. Our 20Ft Air-Cooled Container ESS (500kWh-1MWh) is the ideal modular building block for such deployments. |

| Coastal/Grid-Weak Industrial Parks | Hurricane/outage resilience, high electricity costs, poor grid quality. | Grid-Forming Microgrid with Solar + ESS. A system designed to intentionally island and operate independently from the main grid. | Ensures business continuity during extended outages. Stabilizes local grid voltage and frequency. Optimizes energy costs through arbitrage. Built on robust, containerized ESS platforms for easy siting and hardening against weather. |

Navigating the Certification Maze: A Checklist for Compliance

| Certification Area | Purpose | Why It Matters for Your Project |

| UL 9540 | Standard for Energy Storage Systems and Equipment | Mandatory for fire safety and system approval in most U.S. jurisdictions. The benchmark for insurer and AHJ (Authority Having Jurisdiction) acceptance. |

| UL 1973 | Standard for Batteries for Stationary Use | Certifies the safety of the battery pack itself. A core component of a UL 9540 listed system. |

| IEEE 1547 | Standard for Interconnecting Distributed Resources | Ensures the system safely and reliably connects to the utility grid, managing voltage, frequency, and anti-islanding. |

| NEC (NFPA 855) | National Electrical Code, Article 855 | Governs the installation of stationary ESS, dictating spacing, fire suppression, and signage requirements. |

| FEOC Compliance Docs | Supply Chain Traceability | Paperwork proving battery components meet OBBBA sourcing rules. Essential for securing the ITC. |

Part 4: Frequently Asked Questions (FAQ)

Q: With the OBBBA phasing out solar ITC, is a solar-plus-storage project still economical?

A: Absolutely. While the solar ITC is declining, the storage ITC remains strong at 30%+ through 2036. The combined economics are compelling. Storage allows you to capture and use more of your solar generation, drastically reduce demand charges, and provide backup power. In many high-utility-rate areas, the payback period for a smartly configured solar-plus-storage system is under 5 years, even with evolving incentives.

Q: How can I be sure your battery system complies with FEOC rules?

A: We provide a comprehensive supply chain transparency package with our U.S.-integrated systems. This includes manufacturer’s affidavits, batch traceability for cells, and documentation on critical mineral sourcing. Our technical sales team will guide you through the latest IRS guidance to ensure your project’s cost basis qualifies for the full ITC.

Q: We have an urgent need to power a new data center hall within 18 months. Is that possible with a BTM solar-storage microgrid?

A: Yes, a containerized ESS-based microgrid is the fastest path to power. The key is the "Power Couple" approach. By siting containerized battery and solar systems near an existing grid interconnection point, we can often avoid the multi-year queue for new large-scale interconnection. Pre-fabricated, tested containers can be deployed on-site in months, not years. We focus on this accelerated deployment pathway for critical load clients.

Q: What operational roles can an ESS play for a data center beyond backup?

A: Modern ESS are multi-functional revenue-grade assets. Primary functions include:

1. Peak Shaving: Cutting the highest 15-minute draw from the grid to minimize demand charges.

2. Energy Arbitrage: Charging with cheap off-peak or solar power, discharging during expensive peak periods.

3. Frequency Regulation: Providing fast-responding grid services for additional revenue (in market regions).

4. Renewable Firming: Smoothing the output of onsite solar to make it a more reliable, dispatchable resource.

Part 5: Conclusion: From Vendor to Strategic Partner

The race to power America’s AI future and high-performance industry will be won by those who view energy not as a commodity, but as a strategic asset to be engineered and optimized.

The challenges posed by the OBBBA’s compliance maze and the grid’s inability to scale with AI demand are too complex for a piecemeal, equipment-only procurement strategy. They require a partner with integrated technology, regulatory expertise, and a deployment mindset.

At MateSolar, we define ourselves as a one-stop, full-scope solutions provider. We move beyond supplying hardware to delivering certainty. From initial feasibility and FEOC-compliant system architecture, through seamless deployment of our pre-engineered containerized or hybrid systems, to long-term performance assurance—we are invested in the success of your project.

Your energy challenges are unique. Your solution should be too. Let's build a resilient, compliant, and cost-effective power infrastructure that turns energy from a bottleneck into a competitive edge.

Explore our comprehensive system architectures and scalable products designed for the American market:

- Browse our full range of integrated Solar & Storage Systems.

- Discover the efficiency of our all-in-one Commercial 250KW Hybrid Solar System for midsize applications.

- Learn how our scalable 20Ft Air-Cooled Container ESS (500kWh-1MWh) can serve as the foundation of your large-scale microgrid or "Power Couple" project.