The global energy storage sector is undergoing an unprecedented technological transformation in 2025. With renewable energy penetration accelerating worldwide, energy storage system (ESS) integration has evolved beyond simple capacity expansion to focus on system-level optimization, safety enhancement, and economic viability. The industry is experiencing a fundamental reconfiguration across cell technology, thermal management, system architecture, and intelligent control systems. This article examines the latest developments in ESS integration, supported by empirical data and real-world case studies, while providing insights into future directions for the industry.

1. The Era of Ultra-High-Capacity Cells: 314Ah Becomes Mainstream

The transition from 280Ah to 314Ah cells represents one of the most significant shifts in large-scale ESS design. According to market data, 314Ah cell penetration in projects exceeding 100MWh has surged from 15% in 2024 to 45% in 2025 . This transition is driven by the relentless pursuit of higher energy density and reduced system-level costs.

Technical Advancements and Challenges

The implementation of 314Ah cells has enabled remarkable density improvements. One documented 100MWh project demonstrated that switching from 280Ah to 314Ah cells reduced module counts from 2,000 to 500, decreasing footprint requirements by 35% and cutting overall system costs by 15%.

However, these advancements introduce new engineering challenges. The increased cell weight (reaching 12kg per cell) necessitates reinforced assembly infrastructure, with some manufacturers upgrading from 5kg to 20kg-capacity robotic arms to maintain production efficiency . Thermal management becomes more critical as larger cells exhibit 18% higher temperature rise compared to 280Ah counterparts, requiring innovative cooling solutions to maintain temperature differentials below 5°C.

Table 1: Performance Comparison of Mainstream Energy Storage Cells (2025)

| Parameter | 280Ah Cell (2024 Baseline) | 314Ah Cell (2025 Mainstream) | 500-600Ah Cell (Emerging 2025) |

| Energy Density (Wh/kg) | 160-180 | 180-200 | 200-220 |

| Cycle Life (Cycles) | 6,000 | 7,000 | 10,000+ |

| Project Cost Reduction | Baseline | 15% | 25% (Estimated) |

| Thermal Rise (°C) | 15 | 18 | 20+ (Requires Advanced Cooling) |

| Module Integration Density | 1x | 3x | 5x+ |

| Typical Application | Utility-scale ESS | Utility-scale & C&I ESS | Next-generation utility ESS |

Source: Industry data compilation from multiple manufacturers

2. Liquid Cooling Proliferation: From Niche to Mainstream

Thermal management has become a critical differentiator in ESS performance and safety. Liquid cooling, once limited to utility-scale applications, has seen rapid adoption across commercial, industrial, and even residential segments.

Utility-Scale Advancements

Large-scale energy storage projects have moved beyond basic liquid cooling to advanced micro-channel cold plate technology. These systems feature 2mm flow channels that improve heat transfer efficiency by 40%, reducing temperature differentials from 8°C to 4°C while decreasing coolant requirements by 30% (from 100L/MWh to 70L/MWh).

Dynamic flow control represents another significant advancement. Modern systems incorporate intelligent flow regulation that adjusts coolant delivery based on real-time cell temperature data, reducing pumping energy consumption by 15% and achieving annual electricity savings of approximately ¥120,000 (∼$16,500) for a 200MWh facility.

Commercial & Industrial Applications

The penetration of liquid cooling in C&I applications has jumped from 30% in 2024 to 55% in 2025. This growth is fueled by cost-optimized solutions including simplified plate designs (30% cheaper than micro-channel alternatives) and seasonal operation strategies that utilize natural cooling during winter months, reducing full-time liquid cooling operation from 8 to 5 months and cutting total costs by 25%.

Modular liquid cooling units have emerged as a preferred solution for rapid deployment. Pre-engineered 5MWh liquid cooling units containing all necessary components can be quickly assembled into larger systems, reducing installation time by 40% compared to custom-designed solutions.

Residential System Innovations

The residential segment has witnessed the most surprising adoption of liquid cooling technology. Innovative compact designs featuring 3mm thin cold plates and noise levels below 45dB have made liquid cooling viable for home environments. These systems enable higher charge/discharge rates (1.5C compared to 1C for air-cooled systems), reducing charging time from 10 hours to 6.7 hours for a 10kWh system.

Some manufacturers have integrated thermal synergy between ESS and household heating systems. One solution captures waste heat from battery operation to supplement domestic hot water production, reducing gas consumption by 20% during winter months and increasing the overall value proposition of residential ESS by 30%.

3. System Architecture Optimization: Voltage Platforms and Hybrid Integration

The evolution of cell technology has driven complementary advances in system architecture design. Engineering priorities have shifted toward higher voltage platforms, reduced parallel connections, and hybrid energy storage systems (HESS).

Voltage Platform Evolution

The industry is transitioning from "low-voltage, high-parallel" to "high-voltage, low-parallel" configurations. Using 314Ah cells in 8-series arrangements creates 48V modules that can be series-connected to achieve system voltages of 1,920V, compatible with modern 1,500V power conversion systems (PCS) . This approach improves conversion efficiency from 97.5% to 98.2%, generating approximately 280,000kWh additional annual output for a 200MWh project.

Parallel Connection Challenges and Solutions

Increased parallel connections introduce current imbalance challenges. Some early projects experienced 15% current deviation when paralleling 20+ modules, necessitating the addition of current balancing modules that add 5% to component costs but improve system stability by 20% and extend cycle life by 10%.

Mixed series-parallel architectures have emerged as an alternative approach. One 50MWh C&I project implemented a configuration using 4-series 314Ah cells to form 24V modules, series-connecting 8 of these to achieve 192V, then paralleling 50 sets. This design demonstrated superior current sharing characteristics compared to pure parallel approaches.

Hybrid Energy Storage Systems

The integration of batteries with complementary technologies represents a significant trend in 2025. Battery-supercapacitor hybrids provide enhanced grid response capabilities, with Australia's Hornsdale project achieving 50% faster frequency regulation response using a 129MWh lithium battery paired with a 1.5MW supercapacitor system.

4. BMS and Intelligent Control Upgrades

Battery Management Systems have evolved from basic monitoring platforms to sophisticated predictive control systems capable of multi-chemistry support and real-time safety management.

Advanced Monitoring Capabilities

Sampling frequencies have increased from 1Hz to 10Hz in mainstream projects, enabling earlier anomaly detection. This enhancement provides 5-second advance warning of voltage abnormalities (3 seconds more than previous systems), reducing thermal runaway incidents from 0.3% to 0.1%.

Cross-System Integration

Tighter integration between BMS and PCS has become standard in new installations. Modern systems enable real-time temperature data sharing, allowing PCS to automatically reduce power (from 100% to 80%) when cell temperatures exceed 50°C and initiate shutdown at 55°C. This coordination has increased high-temperature operation duration by 40%.

Multi-Chemistry Support

The growing diversity of cell technologies (including 314Ah, 2800Ah, and emerging chemistries) requires BMS platforms capable of automatic chemistry recognition. Early projects experienced 3% capacity degradation when misapplying charging parameters between different cell types. Advanced algorithms that match voltage platforms and capacity curves now achieve 99.5% recognition accuracy.

Table 2: BMS Functional Evolution in Energy Storage Systems

| Capability | 2024 Standard | 2025 Standard | 2025 Advanced |

| Sampling Frequency | 1Hz | 10Hz | 100Hz (Prototype) |

| Chemistry Recognition | Manual Configuration | Automatic (99.5% Accuracy) | Adaptive Learning |

| Thermal Runaway Prediction | 2-second warning | 5-second warning | 10-second warning |

| PCS Integration | Basic alarm signals | Real-time data sharing | Predictive power adjustment |

| Cycle Life Estimation | ±20% Accuracy | ±10% Accuracy | ±5% Accuracy |

| Communication Protocol | CAN Bus | CAN Bus + Ethernet | Wireless Mesh Networks |

Source: Industry performance data compilation

5. Application-Specific Integration: The Era of Scenario-Based Design

2025 has solidified the trend toward application-specific ESS design with distinct approaches for utility-scale, commercial/industrial, and residential applications.

Utility-Scale: Integrated Energy Hubs

Modern utility-scale projects have evolved into sophisticated multi-function energy hubs. Approximately 90% of new projects exceeding 100MWh now integrate photovoltaic generation, charging infrastructure, and battery diagnostics capabilities.

These integrated facilities demonstrate significant operational advantages. One 200MWh "solar-storage-charging-inspection" project uses solar generation to directly charge batteries (bypassing grid conversion), improving charging efficiency by 5% and saving approximately ¥180,000 (∼$24,700) in annual grid fees.

Advanced diagnostics capabilities provide real-time health monitoring with 98% accuracy, identifying 80% more potential failures compared to quarterly offline testing.

Virtual power plant (VPP) integration has created new revenue streams. One 150MWh facility participating in a VPP program adjusts discharge patterns based on grid requirements (increasing output during peaks and reducing during valleys), generating approximately ¥600,000 (∼$82,300) in annual ancillary service revenue—a 15% improvement over baseline operation.

Commercial & Industrial: Economic Optimization

C&I projects increasingly prioritize economic optimization through sophisticated energy management. One 50MWh installation implements an intelligent electricity price response system that uses 24-hour price forecasting (with 90% accuracy) to optimize charge/discharge cycles. The system maximizes activity when peak-valley price differences exceed ¥0.8/kWh and reduces operation when differences fall below ¥0.5/kWh, increasing annual revenue from ¥1.2 million to ¥1.8 million (∼$164,600 to $246,900).

Self-powering models provide additional value for energy-intensive facilities. A 20MWh system at an electronics manufacturing plant supports 80% of facility loads for 4 hours during grid outages, responding 10 times faster than diesel generators (0.5 seconds versus 5 minutes) and reducing outage-related losses by 60%.

Residential: The Home Energy Hub

Residential energy storage has evolved from simple battery backup to comprehensive home energy management. Modular systems that expand from 5kWh to 20kWh (in 5kWh increments) now represent 70% of sales, significantly outperforming fixed-capacity products.

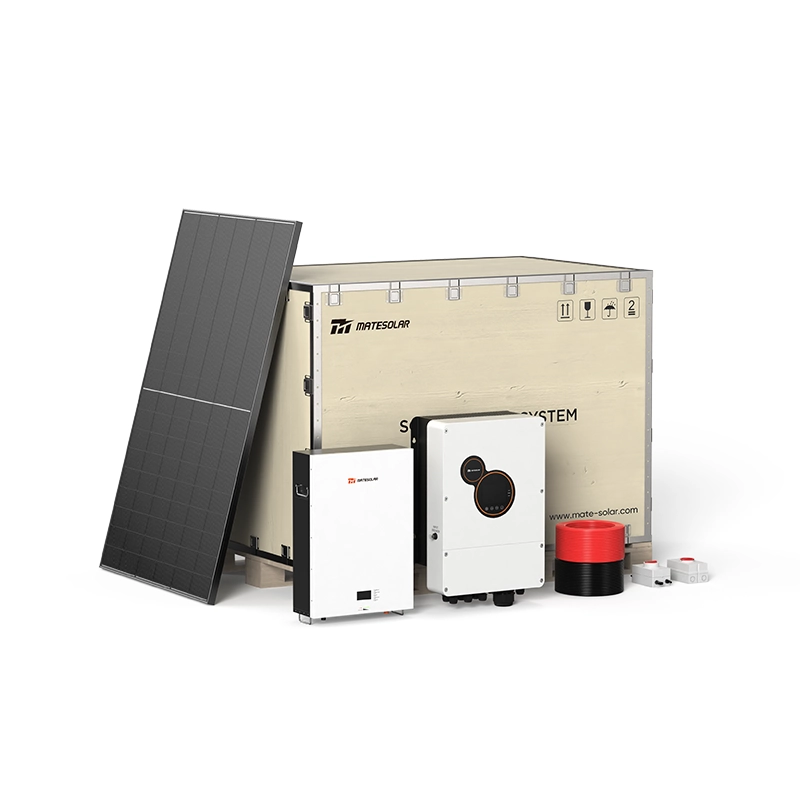

Integrated "solar-storage-charging" systems combine 2kW photovoltaic arrays with 3kWh storage and 7kW charging stations, enabling sophisticated energy flow optimization. During sunny conditions, solar power prioritizes household consumption with excess directed to battery charging and electric vehicle charging. During inclement weather, stored energy powers both home and vehicle needs, reducing grid dependence from 80% to 30%.

6. Safety and Grid Integration Advances

Enhanced safety features and grid support capabilities have become critical differentiators in ESS design.

Advanced Safety Systems

Multi-level protection strategies have become standard across the industry. These include cell-level fusing, module-level isolation, and system-level shutdown capabilities. Early detection systems using gas sensors, temperature sensors, and pressure monitoring provide layered protection against thermal events.

Grid-forming inverters represent a significant advancement in grid support capabilities. These systems provide synthetic inertia and voltage regulation traditionally supplied by rotating machinery, essential for maintaining grid stability as renewable penetration increases.

Regulatory Compliance

Updated standards and regulations have driven enhanced safety features. New requirements include:

- ASIL-D compliance for critical safety functions

- Grid code compliance for voltage and frequency ride-through

- Fire suppression systems specifically designed for lithium-ion batteries

- Environmental containment for coolant and fire suppression materials

FAQ: Addressing Key Industry Questions

1. What driving factors are accelerating the adoption of 314Ah cells?

The transition to 314Ah cells is primarily driven by economic benefits (15% system cost reduction), space savings (35% footprint reduction), and reduced complexity (fewer connections and modules). These advantages outweigh the engineering challenges associated with their implementation.

2. Is liquid cooling technically and economically viable for residential applications?

Yes. Technological advancements have addressed historical limitations through compact designs (3mm thin cold plates), acoustic optimization (<45dB operation), and thermal synergy with household heating. These improvements, combined with supporting 1.5C fast charging, make liquid cooling increasingly attractive for residential applications.

3. How do higher voltage platforms improve system efficiency?

Higher voltage platforms (up to 1,920V) reduce current-related losses, improve compatibility with modern 1,500V PCS, and decrease balance-of-system costs. The efficiency improvement from 97.5% to 98.2% represents significant energy savings over system lifetime.

4. What are the most significant BMS advancements in 2025?

Critical BMS advancements include high-frequency sampling (10Hz), automatic chemistry recognition, predictive safety algorithms, and deep integration with power conversion systems. These capabilities collectively improve safety, performance, and longevity

5. How are hybrid energy storage systems changing grid applications?

Hybrid systems combining batteries with supercapacitors provide millisecond-level response to grid frequency fluctuations, enhanced cycle life (by reducing battery cycling), and improved economic value through participation in multiple value streams

Conclusion: The Path Forward in ESS Integration

The energy storage integration landscape has undergone fundamental transformation throughout 2025. The industry has moved beyond simplistic capacity expansion to sophisticated, application-specific designs that optimize for safety, economics, and performance.

Technological advancements across cell design, thermal management, system architecture, and intelligent controls have enabled this transformation. The successful implementation of 314Ah cells, liquid cooling across all segments, higher voltage platforms, and advanced BMS capabilities represents collective progress toward more viable, reliable, and economical energy storage.

Looking ahead, several trends will likely shape the next phase of ESS integration:

- Continued cell expansion beyond 500Ah requiring novel thermal management approaches

- Enhanced safety systems leveraging artificial intelligence and advanced sensors

- Standardization and modularization to reduce costs and accelerate deployment

- Tighter grid integration through advanced inverters and grid-forming capabilities

- Circular economy considerations including recycling and second-life applications

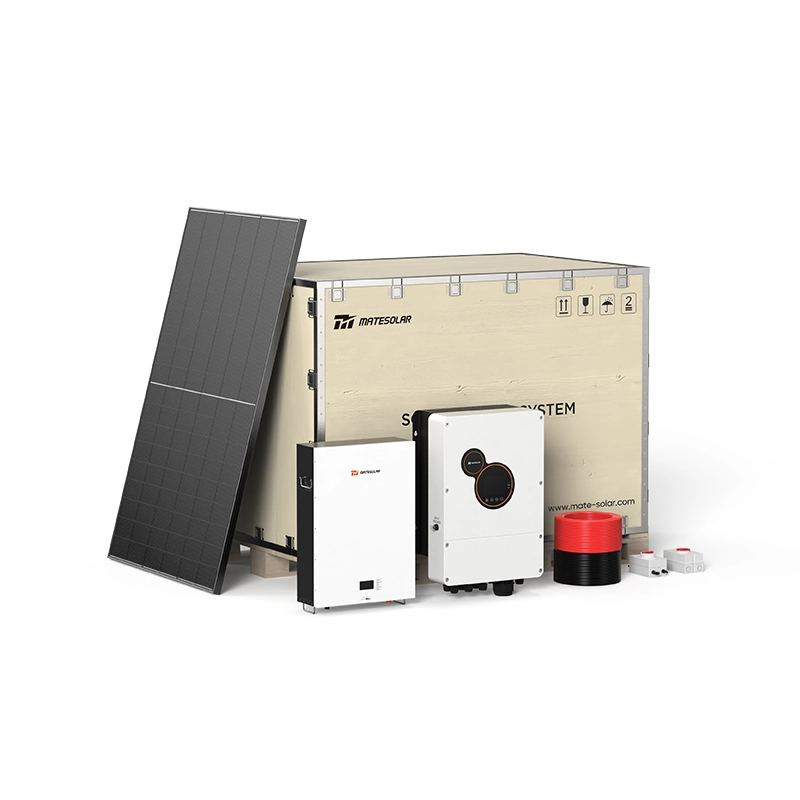

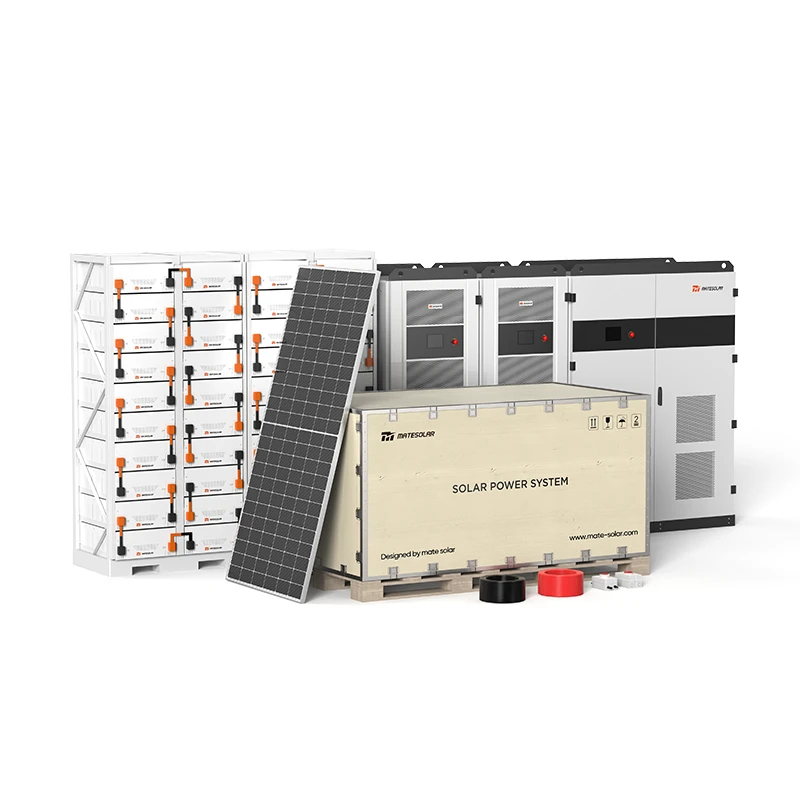

At MateSolar, we integrate these cutting-edge technologies into tailored PV-ESS solutions that address the unique requirements of utility, commercial, industrial, and residential applications. Our comprehensive approach to energy storage integration combines technological excellence with practical implementation experience, ensuring optimal outcomes for our clients.

Discover our innovative energy storage solutions including our advanced 3MWh 5MWh Liquid Cooling Container Energy Storage System

featuring industry-leading energy density and safety features.

→Learn About Our 5MWh Container System

MateSolar is a leading provider of integrated PV-ESS solutions, committed to advancing global renewable energy adoption through innovation, reliability, and comprehensive system expertise.

#EnergyStorageIntegration #314AhBatteryCell #LiquidCoolingTechnology #BMS #SystemOptimization