Navigating the July 31, 2026 Deadline with Unwavering Execution Focus, Not Just Price. An Analysis of Delivery Capabilities, Risk Mitigation, and Partner Selection.

Publication Date: February 4, 2026

Executive Summary:

For developers and investors in Bulgaria's vibrant renewable energy landscape, the clock is now decisively ticking. The allocation of the RESTORE 2 subsidy tranche has set in motion a critical race against time, with a significant portfolio of projects mandated for completion and grid connection by July 31, 2026. This deadline is not a soft target; it is the definitive line separating financial viability, underpinned by crucial state aid, from potential commercial distress. This comprehensive guide, authored with insights from industry execution veterans, moves beyond basic technology comparison. It delves into the paramount challenge of our current market phase: assuring on-schedule, on-budget project delivery. We analyze the systemic risks of supply chain disruption, installation bottlenecks, and regulatory hurdles, providing a framework for evaluating partners based on proven delivery records, product design for speed, and ironclad supply chains. This document serves as an essential blueprint for making partner decisions that protect your subsidy, your investment, and Bulgaria's clean energy ambitions.

I. The Imperative: Understanding the RESTORE 2 Deadline & The Stakes

The RESTORE (Recovery and Sustainability Plan) mechanism has been instrumental in accelerating Bulgaria's energy transition. The conclusion of the second round of funding has created a concentrated pipeline of projects, all converging on the same hard deadline. Failure to achieve commercial operation (COD) by July 31, 2026, risks forfeiting the awarded subsidies, fundamentally undermining project economics.

The Core Anxiety: For a project owner or developer, this translates into a singular, pervasive concern: "Will my chosen equipment supplier and execution partner be able to deliver and perform within the next 17 months?" The market is shifting from a price-centric evaluation to a risk-centric evaluation. The lowest capex bid becomes meaningless if it leads to subsidy loss due to delays.

Table 1: The Cost of Delay – Economic Impact Analysis (Hypothetical 5MW PV + 2MWh Storage Project)

| Szenario | Subsidy Status | Impact on IRR | Key Risk Factors |

| On-Time Commissioning (Before July 31, 2026) | Full grant secured | Baseline IRR (~12-15%) | None related to subsidy. |

| Delay of 3 Months (Oct 2026 COD) | Subsidy potentially forfeited or significantly reduced | IRR reduction of 25-40% | Lost grant income, extended financing costs, missed first-summer production. |

| Delay of 6+ Months (2027 COD) | Subsidy lost, possible PPA renegotiation | Project may become financially unviable | All of the above, plus potential penalties and grid connection agreement issues. |

II. The Three Pillars of Guaranteed Delivery: Evaluating Your Supplier

To mitigate the existential risk highlighted above, due diligence must focus on three non-negotiable pillars.

1. Proven Project Delivery Record & Execution Heritage

A supplier’s track record is the most reliable predictor of future performance. Scrutinize their portfolio for:

- Geographic Relevance: Experience in the Balkan or CEE region, with understanding of local grid codes, certification (BDS, EN), and climatic conditions.

- Scale and Complexity: Evidence of delivering turnkey or complex equipment packages for projects of 1MW+ on time.

- References and Case Studies: Verifiable contact points for past projects. Ask for specific examples of projects delivered under tight timelines.

“A partner’s history is your best insurance policy. Don’t just ask for a brochure; demand a project list with contacts and commissioning dates.”

2. Product Design for Speed: Modularity & Plug-and-Play Architecture

Time spent on complex civil works, custom wiring, and on-site integration is the enemy of the 2026 deadline. The solution lies in pre-engineered, modular solutions.

- For Solar: Look for fully pre-assembled string inverter stations or central inverter skids that arrive on site pre-wired and tested, reducing installation time by up to 60%.

- For Storage: This is where design philosophy is critical. Containerized Battery Energy Storage Systems (BESS) are the standard, but their deployability varies drastically.

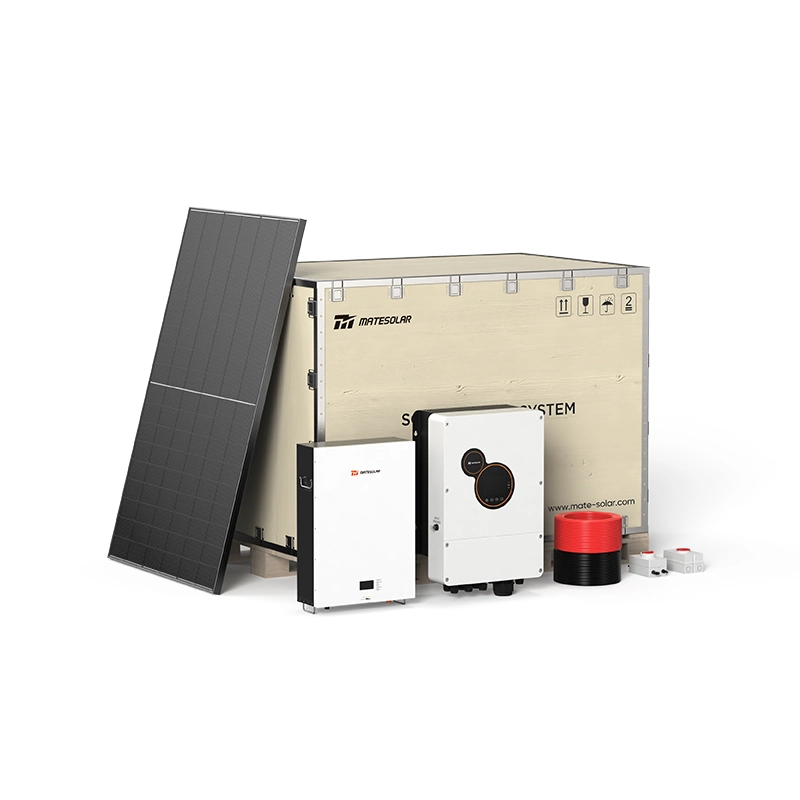

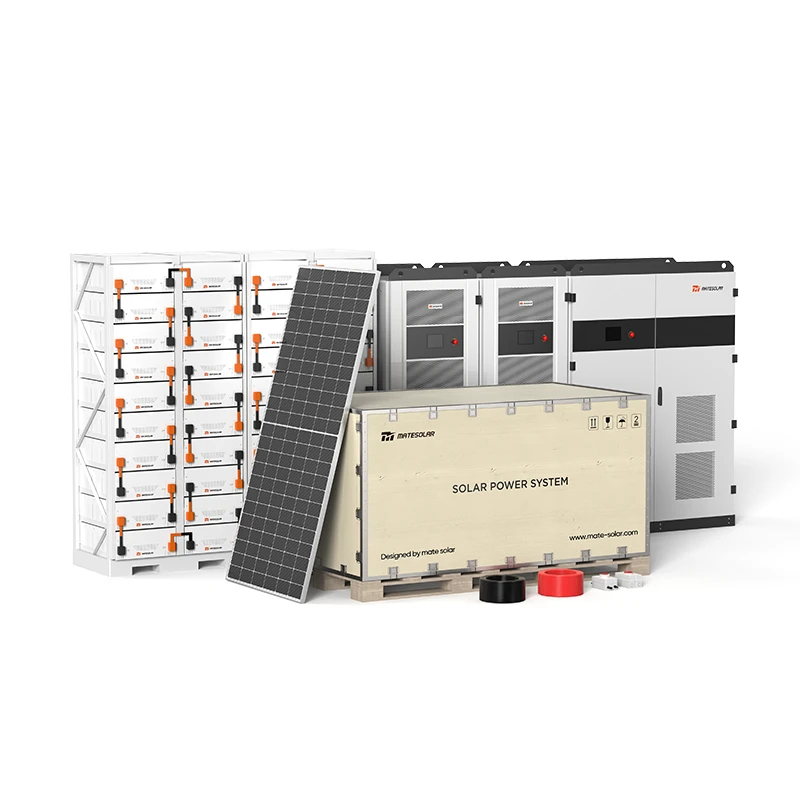

- The Advanced Standard: All-in-One Container ESS. The most time-efficient solutions arrive as a fully integrated, factory-tested power plant in a box. All components—battery racks, PCS, HVAC, fire suppression, and energy management systems—are installed, wired, and commissioned at the factory. On-site work is reduced to placement, grid connection, and final software checks. Our 40Ft Air-Cooled Container ESS (1MWh / 2MWh) exemplifies this approach, designed for rapid deployment in commercial and industrial settings.

- For Maximum Density & Efficiency: For larger-scale requirements, liquid-cooled container solutions offer superior energy density and thermal management. A solution like our 20ft 3MWh / 5MWh Flüssigkeitskühlcontainer-Energiespeichersystem packs more capacity into a smaller footprint while maintaining rigorous thermal control, crucial for cycle life and safety. Its factory-integrated design ensures similar speed of deployment for utility-scale or large C&I applications.

Exploring our dedicated page on Containerized Energy Storage Systems reveals the technical nuances between air and liquid cooling, and their respective installation timelines.

3. Stable, Transparent, and Scalable Supply Chain

The post-pandemic and geopolitical landscape has made supply chain resilience a core competency. Interrogate potential suppliers on:

- Vertical Integration: What key components (cells, modules, inverters) do they manufacture in-house? This grants maximum control over quality and lead times.

- Inventory Strategy: Do they maintain strategic stock of critical components or finished systems in regional hubs (e.g., within the EU)?

- Component Sourcing: What is their strategy for battery cells and power electronics? Partnerships with Tier-1 cell manufacturers are a strong positive indicator.

- Logistics Network: Proven experience in managing freight, customs, and last-mile delivery to Balkan destinations.

Table 2: Supplier Evaluation Matrix for RESTORE 2 Timeline Security

| Evaluation Criteria | High-Risk Supplier Profile | Low-Risk, Delivery-Focused Profile |

| Delivery History | Limited references; vague on past project dates. | Extensive, verifiable portfolio with on-time delivery certificates. |

| Product Philosophy | Custom-designed, site-integrated systems. | Modular, pre-assembled, plug-and-play architectures. |

| Storage System Design | Basic container shells requiring significant on-site fit-out. | All-in-One, factory-commissioned containers (e.g., 40Ft Air-Cooled or 20ft Liquid-Cooled ESS). |

| Supply Chain Transparency | Opaque; reliant on spot-market procurement. | Clear vertical integration or long-term agreements with Tier-1 vendors; regional buffer stock. |

| Project Support | Basic equipment sales. | Offers delivery guarantees, detailed project planning, and local EPC support frameworks. |

III. Beyond the Box: Execution Frameworks & Partnership Models

Selecting the right hardware is only half the battle. The execution model is equally vital.

The "Delivery Guarantee" or "On-Time Commitment" Contract:

Progressive suppliers are now offering contractual commitments tied to delivery milestones. These may include liquidated damages for delays attributable to them or, more powerfully, support mechanisms like providing temporary replacement equipment from regional stock to keep commissioning on track.

The Local EPC Partnership Ecosystem:

The most successful suppliers do not operate in a vacuum. They cultivate and empower a network of trusted local Engineering, Procurement, and Construction (EPC) partners. This model is crucial because:

- Local EPCs possess invaluable knowledge of permitting, local labor, and grid operator relationships.

- The supplier ensures these partners receive deep product training, dedicated technical support, and prioritized logistics.

- It creates a seamless chain of responsibility from factory gate to grid connection.

When evaluating a supplier, ask: "Can you introduce me to your authorized EPC partners in Bulgaria, and provide a case study of a project you completed together?"

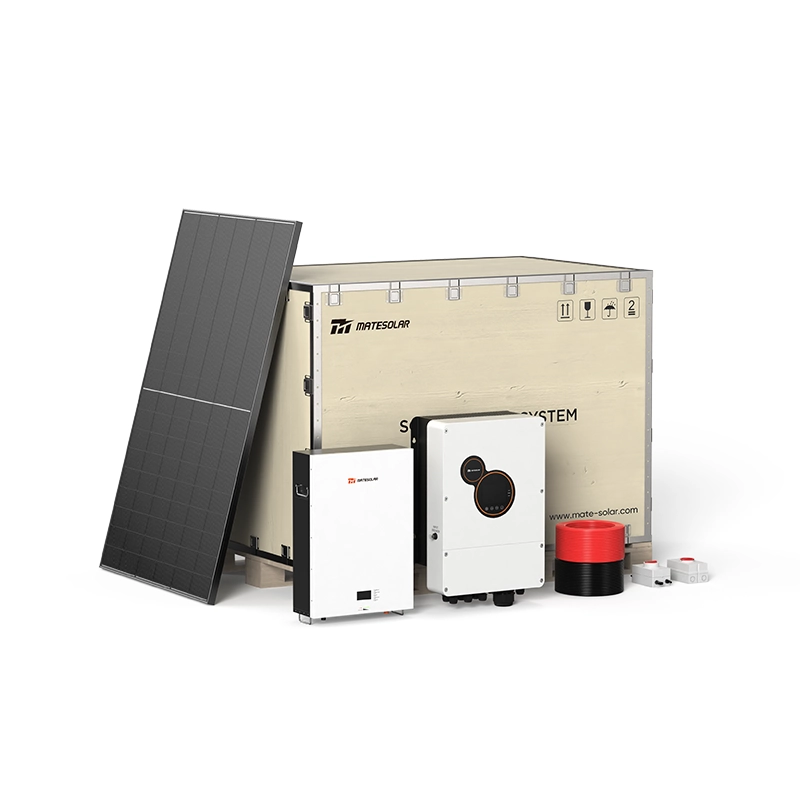

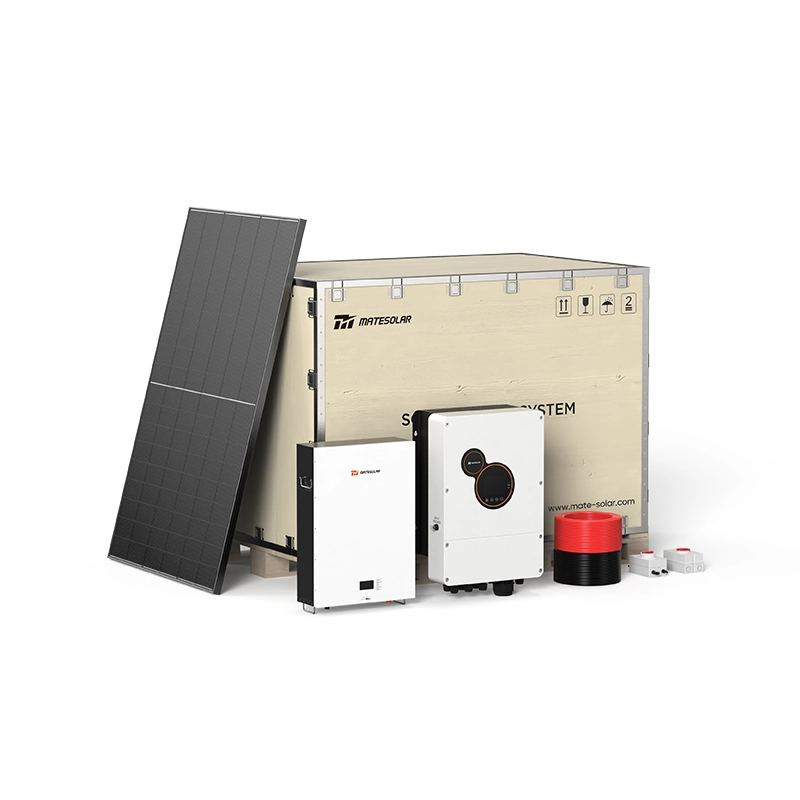

IV. Integrated System Synergy: The Solar-Storage Nexus

For projects combining PV and storage—a growing norm for maximizing self-consumption and grid stability—system-level compatibility is another accelerator. An optimized, pre-designed hybrid system eliminates integration guesswork. For instance, a solution like our Commercial 500kW Hybrid Solar System, which pairs high-efficiency bifacial modules with string inverters and a seamlessly integrated battery bank, is pre-engineered for swift deployment and optimal performance. This holistic approach, part of our broader Solar Photovoltaic & Storage System portfolio, ensures all components communicate flawlessly from day one, shaving weeks off commissioning time.

V. Frequently Asked Questions (FAQ)

Q1: Is the July 31, 2026, deadline absolute, or are there possible extensions?

A: Based on current regulations and communications from the governing bodies, this is a firm deadline for projects awarded under this specific RESTORE 2 tranche. Banking on an extension is an extremely high-risk strategy. Planning must assume the deadline is immutable.

Q2: What are the most common causes of delay we should guard against?

A: The primary culprits are: 1) Equipment delivery delays from suppliers with weak supply chains; 2) On-site installation complexities due to non-modular equipment; 3) Grid connection and commissioning hurdles, often exacerbated by inexperienced installers or incompatible system design.

Q3: How can a "Delivery Guarantee" be enforceable?

A: A well-structured guarantee is backed by clear contractual milestones (e.g., "Equipment delivery to site by Date X") and defined remedies. These can range from financial penalties (liquidated damages) to the supplier's obligation to expedite shipment via air freight or deploy equipment from a local reserve stock at their cost.

Q4: Isn't a local Bulgarian EPC sufficient on their own? Why does the equipment supplier's role matter so much?

A: A competent local EPC is vital. However, if their equipment supplier fails to deliver on time, provides poorly integrated components, or offers slow technical support, the EPC's hands are tied. The supplier sets the foundation for success. The ideal model is a strong triad: Developer + Capable Local EPC + Delivery-Focused Global Supplier.

Q5: For a 1-2 MW project with storage, what is a realistic timeline from contract signing to COD in today's environment?

A: With aggressive but realistic planning:

- Months 1-3: Final engineering, permitting, grid approval.

- Months 4-7: Equipment production and delivery (this is the critical variable based on supplier).

- Months 8-10: Civil works, installation, and mechanical completion.

- Months 11-12: Grid commissioning, testing, COD.

This 12-month timeline is achievable only with a supplier capable of delivering equipment within 4-5 months and offering modular systems.

VI. Conclusion: The Path Forward to July 2026

The period between now and July 31, 2026, will define the winners in Bulgaria's renewable energy sector. The differentiation will not be made on price-per-watt alone, but on execution certainty.

The strategic choice is clear: partner with entities that demonstrate their commitment to your deadline through tangible assets—a documented history of on-time delivery, a product suite engineered for speed, a robust and transparent supply chain, and a supportive partnership model that extends to the local level. This integrated approach is the only reliable mitigant against the severe financial risk of missing the subsidy window.

In this high-stakes environment, your supplier must be a project delivery assurance partner, not just a vendor.

At MateSolar, we understand that in the race against the 2026 deadline, your success is our success. As a global one-stop PV & energy storage solution provider, we combine tier-1, vertically integrated manufacturing with a relentless focus on delivery execution. Our product philosophy is built on modularity and factory integration—from our commercial hybrid systems to our containerized ESS solutions—to dramatically reduce on-site risk and time. We back this with strategic European inventory and a network of trained local EPC partners to ensure your project progresses smoothly from order to operation. We don't just sell components; we deliver commissionable power plants on time, safeguarding your investment and Bulgaria's sustainable energy future.

Contact our Project Delivery Team today to discuss your project timeline and our tailored delivery assurance programs.