How advanced hybrid systems are transforming energy resilience and economics for factories worldwide?

In an era of increasing energy volatility and sustainability demands, factories and industrial facilities face a perfect storm: rising electricity costs, grid instability, and pressure to decarbonize. Traditional solutions fall short—solar alone can't provide 24/7 power, storage insufficient for long outages, and diesel generators become prohibitively expensive to run continuously. The answer lies in integrating these technologies into a seamless, intelligent system that delivers both unprecedented reliability and significant cost savings.

The Convergence of Need and Innovation

Global industrial electricity demand is surging, with a 4.3% increase in 2024 alone compared to 2023 levels. For energy-intensive manufacturers, power expenses can represent over 20% of operational costs, creating an urgent need for both stability and savings. Simultaneously, frequency and duration of power outages are increasing in many regions, particularly in emerging markets where production losses from grid instability can cripple manufacturing operations.

The hybrid solar wind energy storage market size, which includes these integrated systems, was valued at USD 2.4 billion in 2025 and is expanding at a CAGR of 8.3% during the forecast period of 2026-2035. This growth is fueled by landmark legislation worldwide, including Europe's REPowerEU Plan and the U.S. Inflation Reduction Act, which offer long-term tax credits, loan guarantees, and grants that de-risk investments in hybrid energy systems.

Technological Breakthroughs Making Integration Possible

Advanced Component Technologies

Today's integrated systems represent a quantum leap from past solutions. The foundation consists of three complementary technologies:

Today's integrated systems represent a quantum leap from past solutions. The foundation consists of three complementary technologies:

- N-type TOPCon solar panels with conversion efficiencies exceeding 23%, generating more power in limited space

- Phosphate iron lithium (LFP) battery systems with cycle lives of 8,000+ cycles and declining costs that have fallen over 60% in the past five years

- Low-noise, high-efficiency diesel generators with automated start-stop functionality and emissions control systems

Intelligent Control Systems

The true revolution lies in the sophisticated energy management systems (EMS) that orchestrate these components. Modern microgrid controllers can perform seamless switching between power sources in under 20 milliseconds—faster than most sensitive industrial equipment can detect. These systems leverage artificial intelligence to optimize energy flows based on weather predictions, electricity pricing, production schedules, and equipment maintenance needs.

The Business Case: Beyond Backup Power

Comprehensive Cost Reduction

The economic advantage of solar-storage-diesel integration stems from multiple revenue streams and cost avoidance mechanisms:

Table: Value Streams for Industrial Solar-Storage-Diesel Systems

| Value Stream | Mechanism | Воздействие |

| Пиковая экономия | Charge batteries during off-peak hours, discharge during peak | Typical ROI period of 4-5 years in Chinese industrial applications |

| Снижение платы за потребление | Smooth load curves to avoid transformer capacity penalties | Reduces demand charges by 30-50% in high-load fluctuation scenarios |

| Emergency Power | Automatic switchover during grid outages | Prevents production losses from power interruptions |

| Ancillary Services | Participation in grid frequency regulation markets | Additional revenue streams; £45/kW annual fixed returns in some European capacity markets |

| Fuel Savings | Optimized diesel generator operation | One project reduced diesel runtime from 24 to 5 hours daily |

Quantifiable Project Economics

Real-world implementations demonstrate compelling financial returns. A resort in Southeast Asia implemented a system using 3 units of ZXPG E260C8 energy storage cabinets (125kW/261kWh each) alongside 300kW of solar and 500kW diesel generators. The results were dramatic: diesel generator operation decreased from 24 hours/day to just 5 hours/day, while achieving black start capability in under 30 seconds and 99.99% power availability for critical loads.

In Zhejiang, China, a manufacturing facility configured with a 261kWh storage system operating under a 10kV industrial electricity price (with peak-valley price difference of 0.9 RMB/kWh) can generate approximately 470 RMB daily through two charge-discharge cycles, yielding an investment payback period of approximately 4-5 years.

System Architecture and Configuration

Component Sizing for Different Industrial Profiles

Successful implementation requires right-sizing each component based on specific operational needs:

Table: Recommended Configurations for Different Industrial Applications

| Factory Type | Солнечная мощность | Вместимость хранилища | Diesel Backup | Key Considerations |

| Chemical Processing | 5-8MW | 10-20MWh | 2-4MW | 24/7 operations require robust backup; high thermal loads |

| Textile Manufacturing | 3-5MW | 5-10MWh | 1-2MW | Consistent daytime operation; substantial ventilation needs |

| Центры обработки данных | 4-6MW | 8-15MWh | 3-5MW | Ultra-high reliability requirements; potential for liquid cooling |

| Automotive Assembly | 6-10MW | 15-25MWh | 3-5MW | High energy intensity; production line sensitivity to voltage fluctuations |

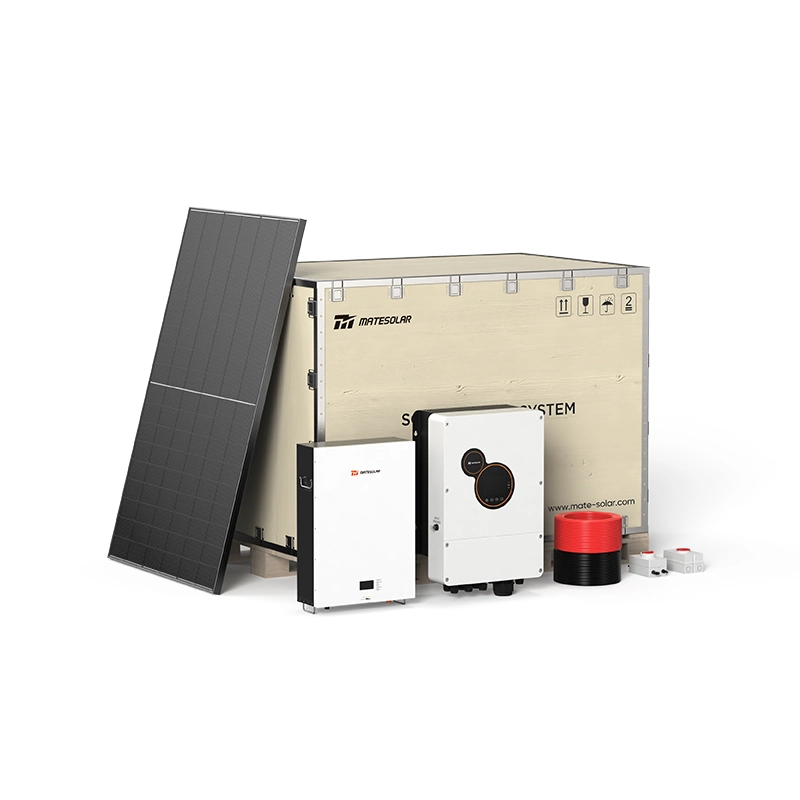

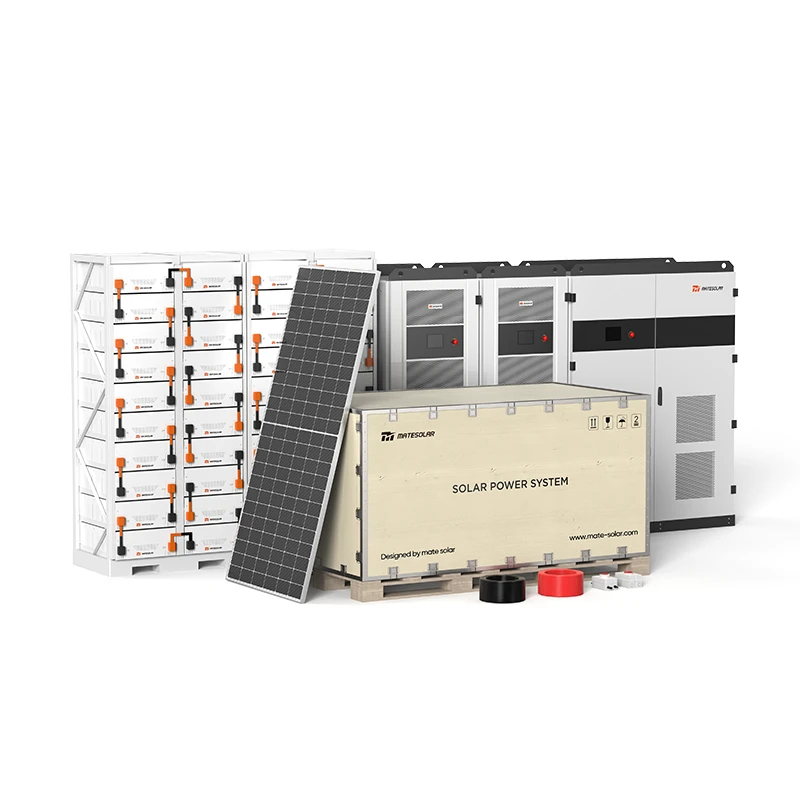

Containerized and Prefabricated Solutions

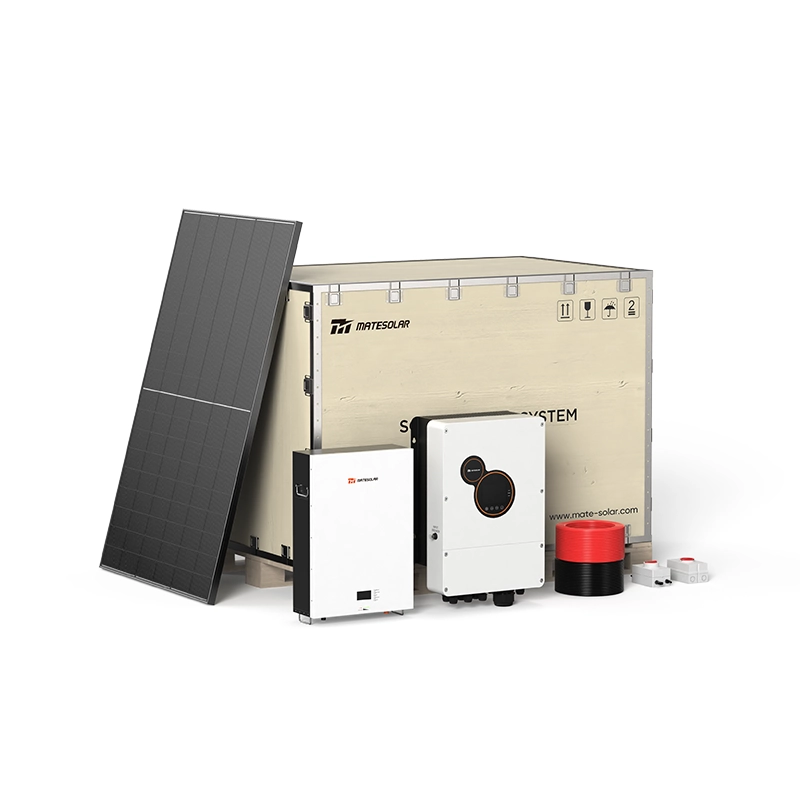

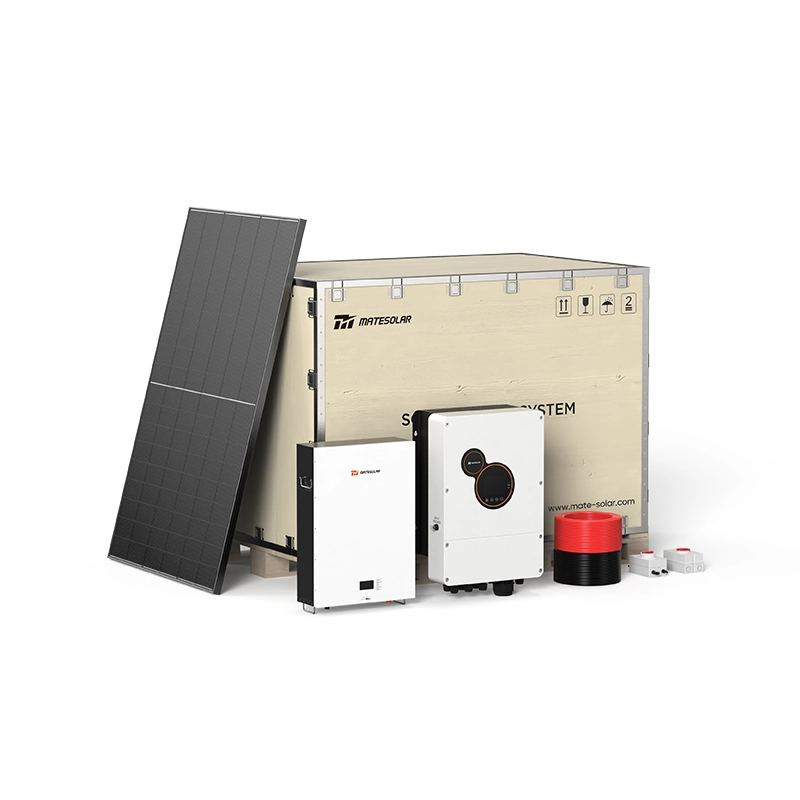

The industry is moving toward standardized, pre-integrated solutions that dramatically reduce installation time and complexity. Companies like East Group Co., Ltd. have developed "All in one" integrated designs that combine energy storage, power generation, control, and protection functions in single enclosures. These systems require "no complex splicing" and can be "quickly put into use upon installation," specifically tailored for industrial and commercial energy storage scenarios.

These containerized solutions support both horizontal capacity expansion (supporting up to 4 battery cabinet clusters) and vertical power expansion (with up to 4 systems capable of AC-side parallel connection, increasing power from 130kW to 520kW). This flexibility allows factories to scale their energy infrastructure alongside production capacity expansion.

Implementation Roadmap for 2026

Policy and Timing Considerations

With the evolving regulatory landscape, timing implementation correctly can significantly impact project economics:

- Complete project filing by Q4 2025 to lock in 2026 equipment procurement prices and avoid potential cost fluctuations from silicon and lithium price volatility

- High-energy consumption factories can secure green credit interest rates 50 basis points lower with appropriate configurations

- Data centers opting for "solar-storage-diesel + liquid cooling" solutions can reduce PUE values to below 1.2, qualifying for additional land policy benefits

Technical Implementation Phases

1. Energy Assessment (4-6 weeks): Comprehensive audit of load profiles, operational schedules, and site conditions

2. System Design (6-8 weeks): Customized engineering of optimal technology mix and control strategies

3. Financing Structuring (4-8 weeks): Securing appropriate incentives, loans, or exploring third-party ownership models

4. Installation (8-16 weeks): Staged implementation to minimize production disruption

5. Commissioning and Optimization (2-4 weeks): Fine-tuning based on actual operation data

Future Evolution: The Road Ahead

The technology continues to advance rapidly. Emerging developments include:

- Virtual Power Plant (VPP) integration: Distributed solar-storage-diesel microgrids are gaining capability to participate in electricity spot market transactions and grid auxiliary services, creating additional revenue streams

- Long-duration energy storage: Flow batteries and other technologies supported by U.S. Department of Energy funding initiatives aim to provide 8+ hours of storage duration

- AI-driven optimization: Artificial intelligence can reduce the time required for commercial power plant licensing and design by up to 50%, accelerating deployment timelines

- Hydrogen hybridization: Emerging solutions explore using excess renewable generation to produce hydrogen for long-term storage or as a cleaner alternative to diesel

FAQ: Addressing Key Implementation Questions

Q: How quickly can the system switch to backup power during a grid outage?

A: Modern systems with advanced Power Conversion Systems (PCS) and Static Transfer Switches (STS) can achieve seamless switching in under 20 milliseconds—sufficient to prevent disruption to even sensitive manufacturing processes.

Q: What operation and maintenance requirements should we anticipate?

A: Cloud-based monitoring platforms enable remote management, with features including "fault early warning, energy consumption analysis, and intelligent dispatch" that can improve operational efficiency by 60%. Most systems require only quarterly inspections and preventative maintenance.

Q: How does this support sustainability goals while still using diesel?

A: Diesel serves strictly as backup rather than a primary source, with one project demonstrating reduction in diesel operation from 24 hours/day to 5 hours/day. As renewable hydrogen and biofuels become more available, these can increasingly displace conventional diesel.

Q: What financing options are available?

A: Multiple models exist, including direct ownership, third-party ownership through Energy Service Company (ESCo) arrangements, and emerging options like "asset investment" and "financial leasing" models that attract social capital. The U.S. Department of Energy also offers various funding programs supporting energy storage innovations.

Q: How is system safety ensured?

A: Comprehensive protection includes "three-level fire protection systems" with built-in "precision liquid cooling temperature control" that maintains battery cell temperature differentials within 3°C, plus additional "aerogel thermal insulation and flame retardant" materials at the PACK level.

Conclusion: The Strategic Path Forward

Industrial solar-storage-diesel integration represents more than an energy project—it's a strategic competitive advantage. By ensuring operational resilience against grid instability while significantly reducing electricity costs, these systems directly impact bottom-line performance. The convergence of improved technology, favorable economics, and supportive policies makes 2026 the ideal implementation window.

Forward-thinking industrial operators should begin with a comprehensive energy assessment to identify their optimal configuration. With project development timelines typically spanning 6-9 months from conception to commissioning, now is the time to position your facility for energy independence and cost optimization.

For organizations considering their options, exploring scalable solutions like Google's system-agnostic солнечные фотоэлектрические системы хранения энергии provides a future-proof foundation. Similarly, modular

1MWh-2MWh BESS (Battery Energy Storage Systems

offer flexible capacity to match specific industrial load requirements while maintaining expansion potential.

MateSolar delivers comprehensive industrial energy solutions through integrated solar-storage-diesel systems, helping manufacturers achieve both energy resilience and cost reduction goals. Our expertise spans project design, financing optimization, and implementation, ensuring clients maximize returns while future-proofing their operations against energy uncertainty.