Accurate load calculation remains the most critical—and often most error-prone—phase in solar-storage system design. Underestimating demand risks crippling performance; oversizing inflates CAPEX by up to 30% while sabotaging ROI. As renewables penetration surges past 35% in leading grids, next-generation computational frameworks are emerging to replace legacy methods like static unit-gauging and coefficient-based approximations. These new paradigms fuse real-time telemetry with predictive analytics to deliver surgical precision in system sizing—a revolution where MateSolar is pioneering transformative standards.

The Calculus of Modern Energy Demand: Beyond Rule-of-Thumb

Traditional load calculation crudely summed nameplate ratings or applied flat derating coefficients (e.g., 0.7–0.9 need factors). Today’s methodologies demand multidimensional modeling:

Dynamic Resource Profiling

Spatiotemporal solar modeling now integrates geocoordinates, tilt angles, and meteorological dynamics. Temperature-induced efficiency decay—approximately 0.4% per 1°C rise—is calibrated against historical weather patterns to predict hourly yield curves.

Stochastic Load Sequencing

Industrial loads exhibit volatility coefficients of 1.2–1.5. AI-driven tools like BP neural networks forecast demand surges within 10% error margins, enabling proactive storage dispatch.

Grid-Interactive Resilience Metrics

With grid SCR (Short-Circuit Ratio) instability events rising 47% since 2023, systems must validate fault current contributions (150–200% of inverter ratings) and THD compliance (<5%) during sizing.

The MateSolar TriVector Analysis Framework

Our methodology dissects load calculation across three axes—temporal granularity, system efficiency, and grid dynamics—using proprietary computational engines:

1. Temporal Load Resolution

Decomposes 8760-hour load profiles into 15-minute intervals, correlating with irradiance volatility. Machine learning identifies recurring patterns (e.g., manufacturing shift changes) to optimize storage cycling.

2. System Loss Topology Mapping

Quantifies cumulative efficiency decay across 11 nodes—from cell-level PID degradation to transformer hysteresis losses. Our digital twin platform updates these coefficients in real-time using IoT-field data.

3. Grid-Forming Readiness Index

Validates system stability against IEEE 2800 standards for critical capabilities:

- Voltage inertia response time: <2s

- Black start capability: <10 minutes

- SCR compatibility: Down to 1.2

Table: Key Metrics in Modern vs. Traditional Load Calculation

| Parâmetro | Legacy Methods | MateSolar 3D Analysis |

| Time Resolution | Monthly averages | 15-minute intervals |

| Efficiency Modeling | Fixed derate (0.75) | Dynamic nodal loss tracking |

| Peak Demand Prediction | +30/-50% error | ≤10% error |

| Grid Stability Compliance | Retroactive validation | Preemptive certification |

| Storage Cycle Optimization | Fixed DoD (80%) | AI-adaptive cycling (C-rate ≤0.8) |

Case Evidence: Precision in Practice

Project: Arctic Food Cold Storage (Nome, AK)

- Challenge: −40°C ambient temps; 5400Pa snow loads; 3.2MW peak demand variance

- Solution:

- Deployed HJT modules with 26.61% efficiency and −0.24%/°C thermal coefficient;

- LOLP modeling set at 0.01 using 14-day autonomy reserve;

- GFM inverters with 98ms VRT response

- Outcome: 94% self-sufficiency despite 18-day polar night; BOS costs reduced 22% via optimal inverter loading ratio (1.1:1).

Project: Textile Mill (Bangladesh)

- Challenge: 35% harmonic distortion from legacy motors; 1.8MWh daily backup need

- Solution:

- Real-time soiling sensors triggering robotic cleaning when losses >5%;

- Active harmonic filters with 97% cancellation;

- Non-linear load sequencing to limit inrush currents.

- Outcome: Achieved THD<3%; storage degradation slowed to 2%/year

Technical Brief: Q&A on Advanced Load Calculation

Q: How does LOLP methodology differ from conventional autonomy days?

A: Where "3-day autonomy" arbitrarily fixes storage capacity, LOLP (Loss of Load Probability) quantifies reliability as a probability metric (0–1). Using stochastic modeling of historical outages and solar resource volatility, it computes exact storage to achieve target reliability (e.g., LOLP=0.001 = 99.9% uptime).

Q: Explain grid-forming’s role in load calculation.

A: Grid-forming (GFM) inverters—unlike grid-following—create voltage/frequency references. When sizing, GFM demands 25–40% oversizing to deliver critical inertia (≥2s) and fault current (≥150% rating). Our tests show Huawei’s FusionSolar 9.0 enables SCR 1.2 stability versus industry-standard 2.5.

The AI-Optimization Layer

MateSolar’s NeuralSizer platform deploys two algorithmic engines to transcend static calculations:

- PSO (Particle Swarm Optimization)

Iteratively tests 10,000+ configuration permutations to minimize LCOE while honoring constraints like roof area or tariff structures. Reduces storage cycling stress by 40%.

- Digital Twin Synchronization

Continuously calibrates models using field data—from module-level mismatch losses to battery SOH drift. Cuts design vs. as-built variance by 40%.

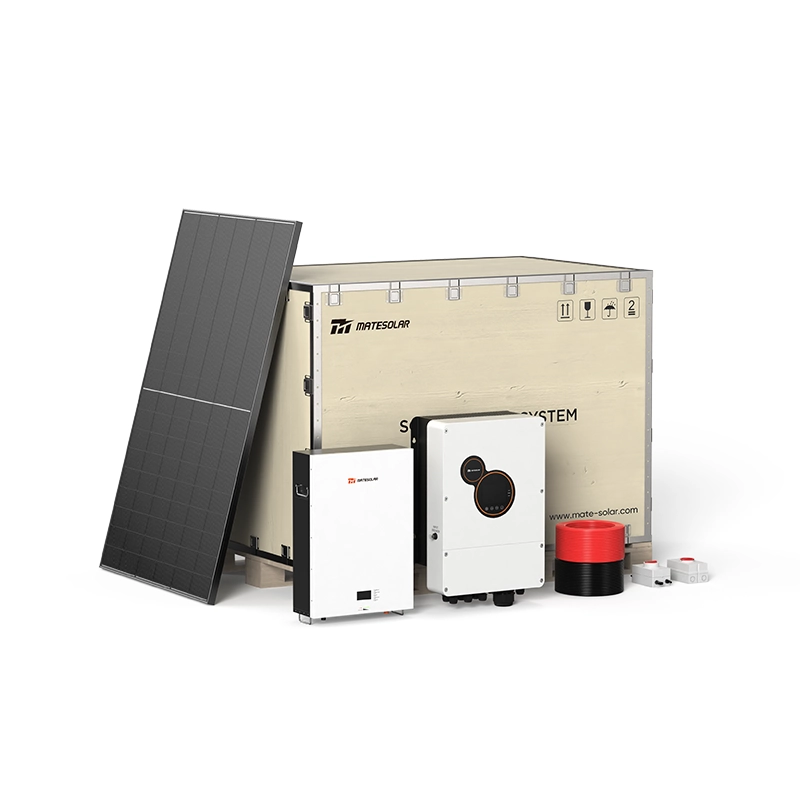

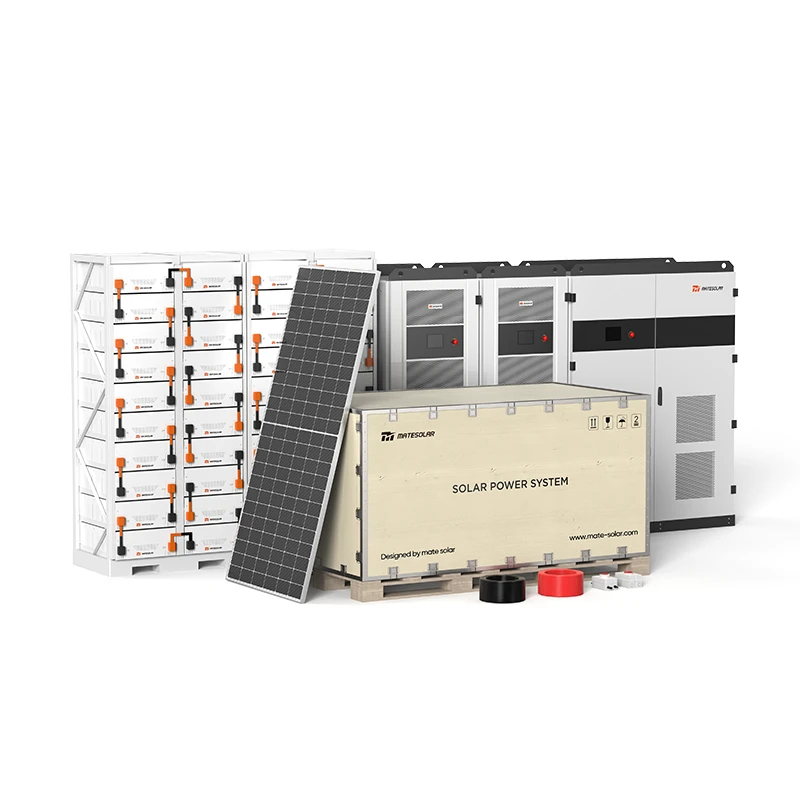

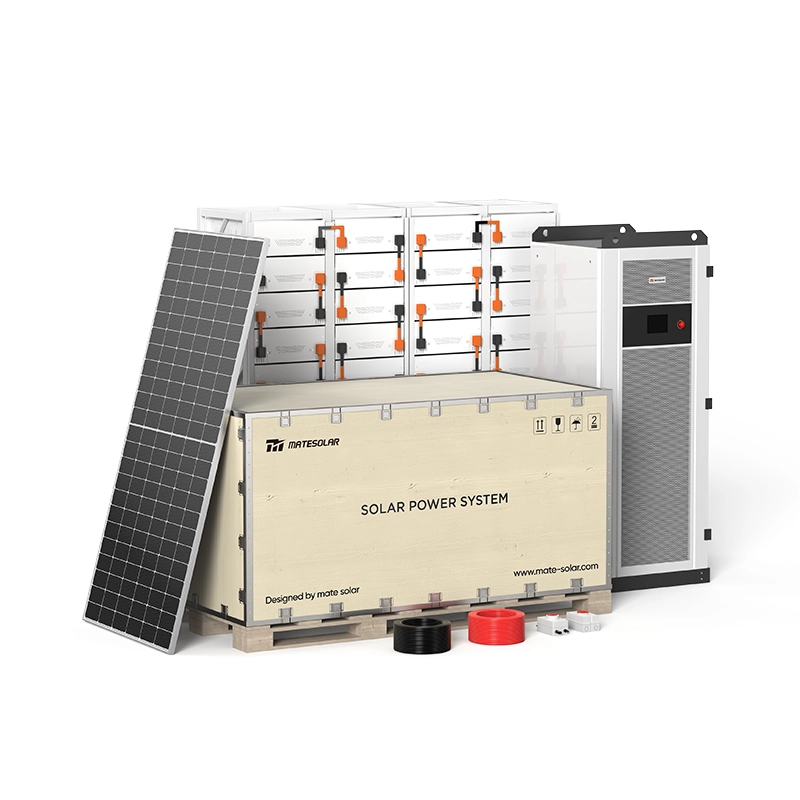

MateSolar: Architecting the Grid-Forming Future

At MateSolar, we engineer integrated solar-storage ecosystems that transcend component-level thinking. Our solutions embody three pillars:

1. True Grid-Forming Foundation

Inverter-native GFM capabilities deliver IEEE 2800-compliant stability—supporting black starts in <10 minutes and SCR 1.0 weak grids.

2. Intelligent String-Level Management

Patented differential power processing eliminates mismatch losses, boosting yield 7% versus central topologies.

3. Cyber-Physical Optimization

Fusion of PV forecasting (85% 24h accuracy), market price signals, and storage degradation models maximizes revenue in VPP applications.

Never Compromise Between Resilience & ROI

The era of oversized, underperforming solar-storage systems ends with computational precision. MateSolar’s load intelligence platform transforms irradiance variability and load volatility from design uncertainties into quantified advantage—proving sustainability and profitability converge at the kilowatt-hour.