For decades, rural communities around the world have faced an energy access paradox: abundant renewable resources, but persistent electricity scarcity. Traditional grid extensions remain economically unfeasible for the 80% of people without electricity, while early solar home systems often fail to meet the needs of agricultural loads or income-generating activities. Now, the convergence of modular battery technology, AI-driven management systems, and innovative financing is giving rise to a new model—villages can operate resilient microgrids that rival urban grid reliability but at half the cost.

The Technology Evolution: From Off-Grid to Intelligent Microgrids

First Wave: Basic Off-Grid Systems (Pre-2020)

Early solar deployment prioritized lighting and basic appliances. Systems lacked storage intelligence, had limited run times, and were prone to failure on cloudy days. Diesel hybrid vehicles are still common, hindering the achievement of emissions targets.

Second Wave: Grid-Tied Rooftop PV (2020-2025)

Programs like Rajasthan’s solar irrigation initiative demonstrated scalability:

<1> 463 MW installed across 243 plants, serving 177,000 farmers;

<2> 60% reduction in agricultural power subsidies. Yet grid instability persisted. During monsoon periods, 37% of generated solar was curtailed due to voltage fluctuations—a problem requiring storage buffers.

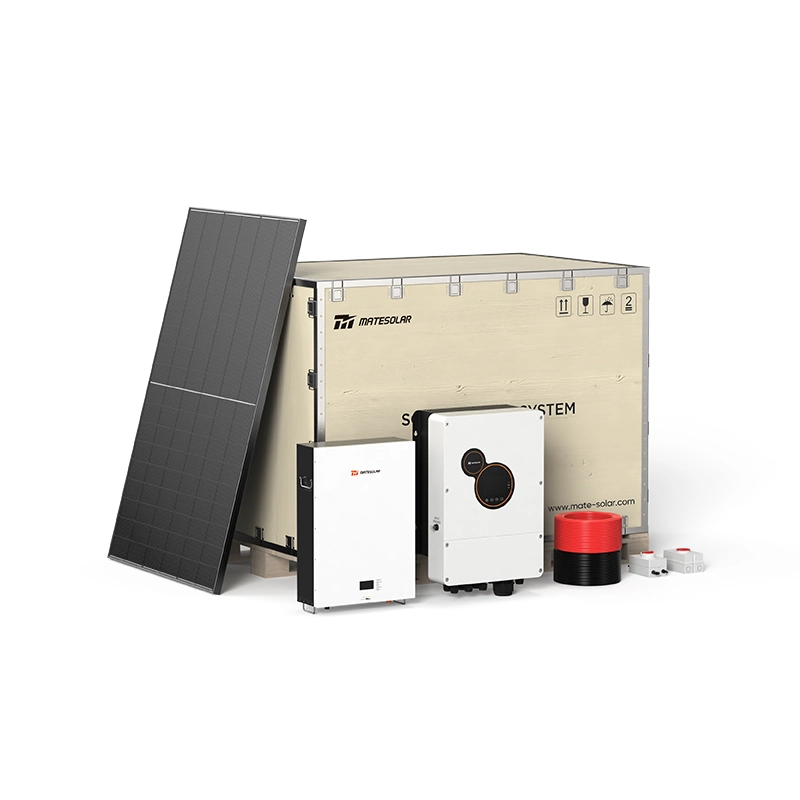

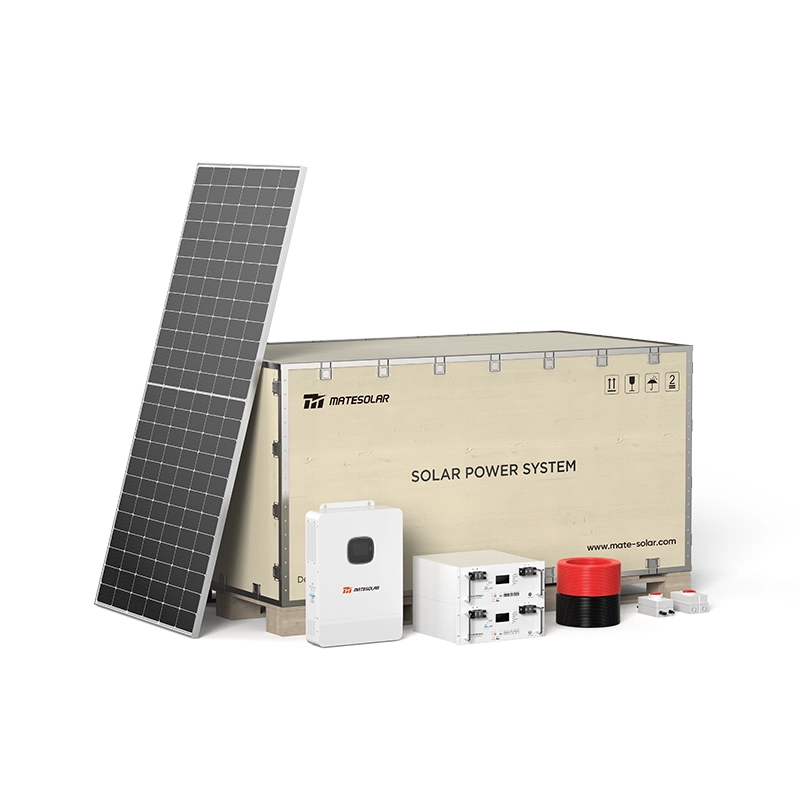

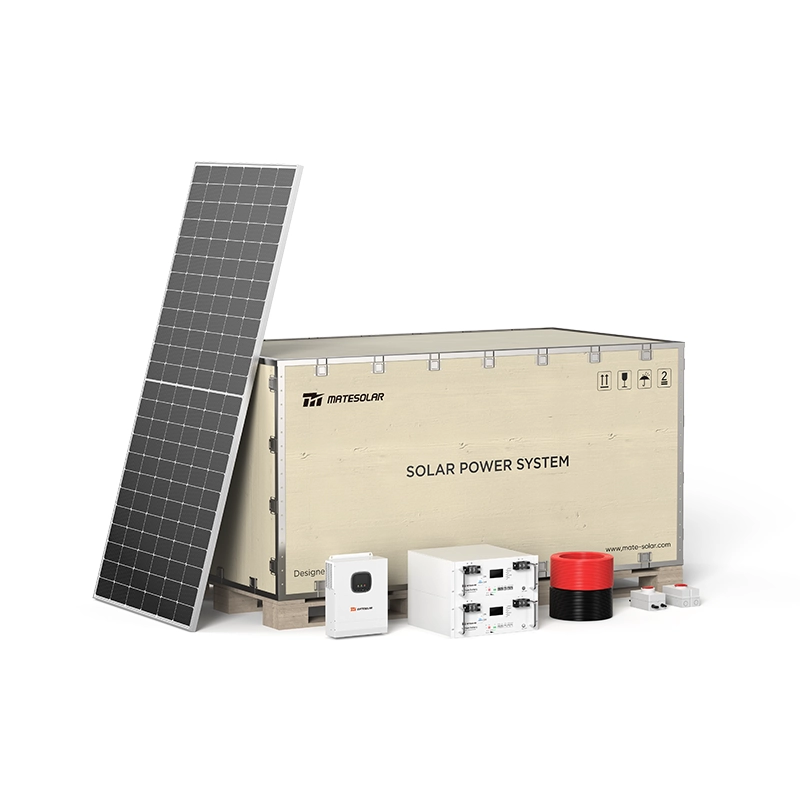

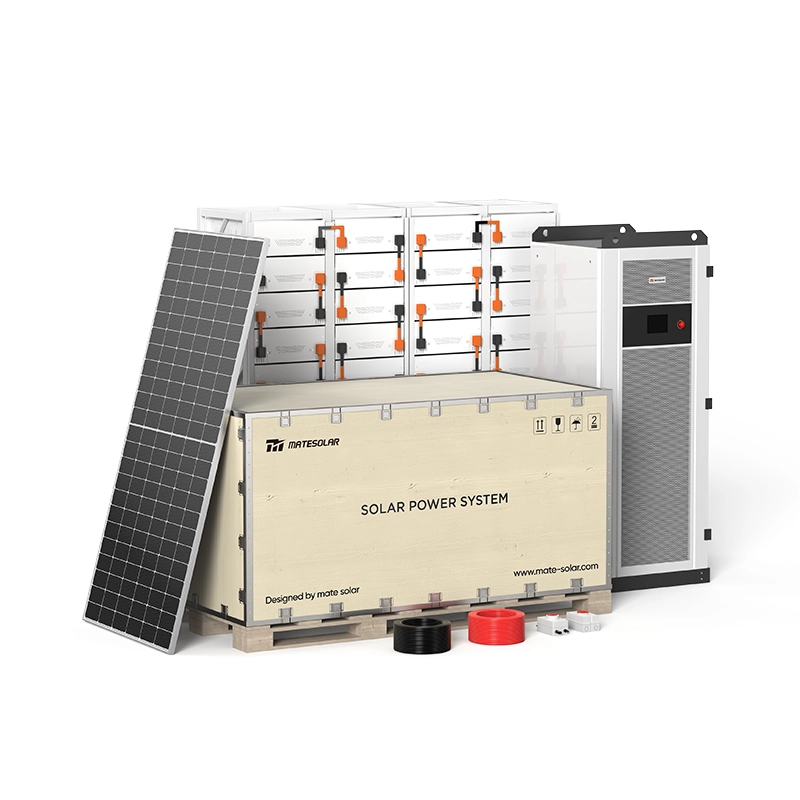

Third Wave: Modular Storage-Integrated Microgrids (2025-Present)

Modern solutions embed four critical innovations:

1. Battery-Powered Grid Formation: Huawei’s smart string storage achieves 99.9% PCS availability with distributed thermal control (ΔT<3°C), extending lifespan by 50%.

2. Agricultural Load Coordination: AI controllers sync water pumping, milling, and processing with solar generation peaks, reducing diesel dependency by 94%.

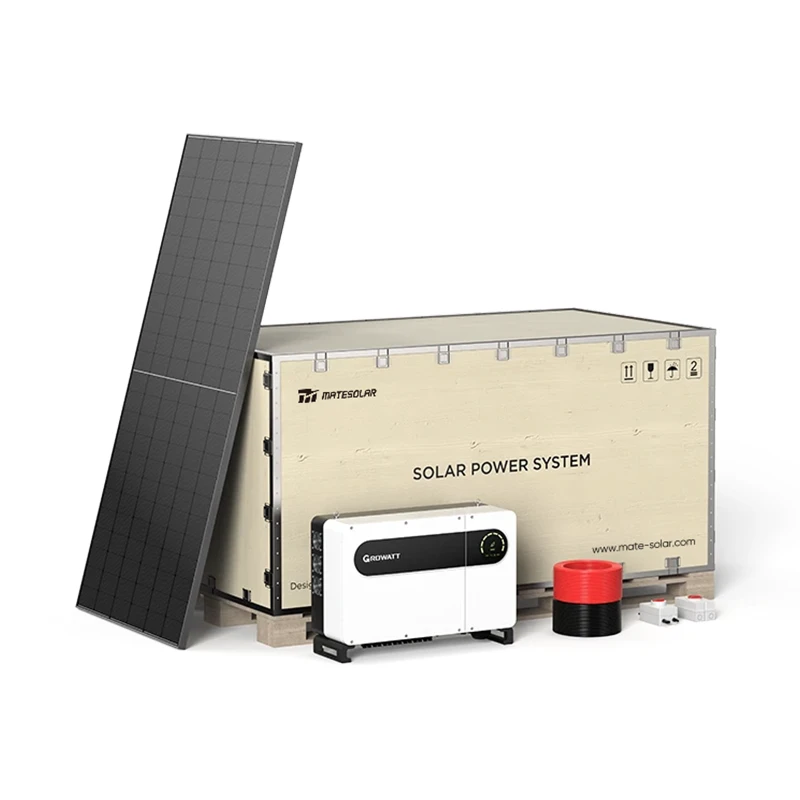

3. Plug-and-Play Architecture: Pre-certified DC blocks enable village-level deployment in <72 hours.

4. Dynamic Tariff Systems: Compensation algorithms pay farmers 200-300% premiums for shifting flexible loads to sunny periods.

Key Innovations Driving Adoption

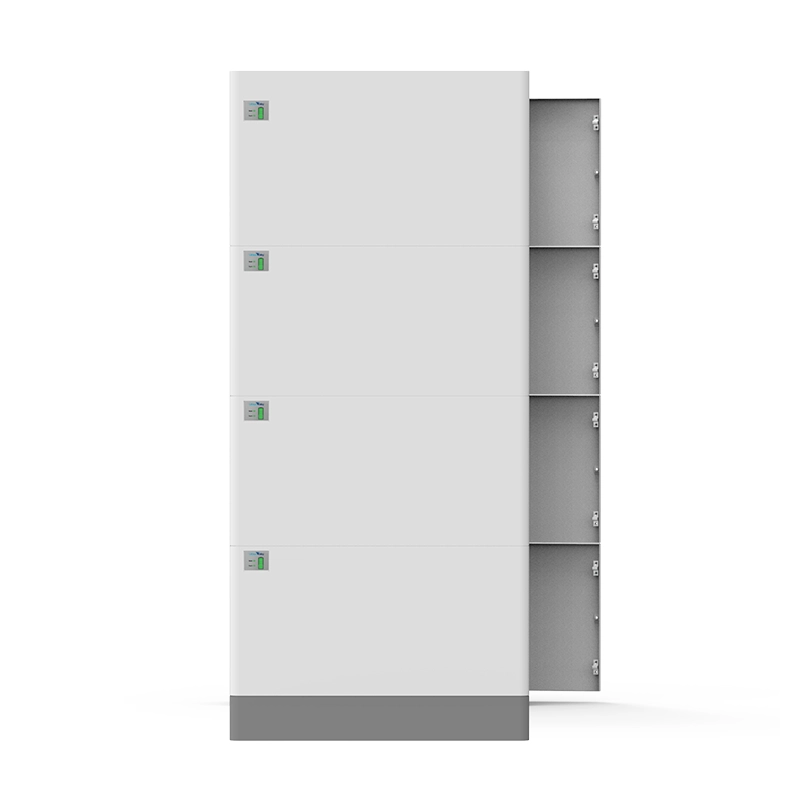

1. Modular Battery Systems: The Game Changer

Global BESS deployments will grow nine-fold by 2040, with costs plummeting to $60/MWh—making storage-backed solar cheaper than diesel in 89% of rural applications. Modular designs dominate:

Table: Modular vs. Traditional Storage Economics

| Parameter | Traditional BESS | Modular BESS (2025) |

| Installationszeit | 8-12 weeks | <72 Stunden |

| Scalability Increment | 500 kWh | 5 kWh |

| Maintenance Cost Reduction | Basislinie | 62% |

| Cycle Life at 35°C | 4,000 cycles | 12,000 cycles |

| Fault Containment | System shutdown | Single-pack isolation |

Source: Frost & Sullivan Modular ESS Whitepaper 2025

2. AI-Optimized Resource Stacking

China’s two-stage stochastic robust optimization (TS-SRO) framework cuts energy costs by 37.6% and CO₂ by 85.3% through:

<1> k-means clustering of 8,760 historical weather scenarios;

<2> Uncertainty budgets adjusting for load volatility

MateSolar’s neural networks extend this further, predicting irrigation demand within 2% accuracy using soil moisture/crop data.

3. Business Model Reinvention

<1> Energy-as-a-Service (EaaS): Farmers pay $0.12/kWh for “solar assurance” versus $0.21/kWh for diesel;

<2> Carbon-for-Crops Swaps: Verified emission reductions fund community seed banks (e.g., 6,300 tons CO₂ → 48 tons drought-resistant maize in Kenya).

Proven Impact: Global Deployment Snapshots

Rajasthan, India – Agricultural Productivity Revolution

<1> 20,000 solar pumps in Kotputli-Behror eliminate diesel for irrigation;

<2> 94% reduction in power cuts despite 225 new connections daily;

<3> $283M mobilized via blended finance ($223M private capital).

Shandong, China – Rooftop-Driven Rural Industry

<1> 68 MW distributed PV across 65 timber factories in Tanyi Town;

<2> $4.08M/year electricity savings with 6,000-ton CO₂ reduction.

Philippines – Utility-Scale Validation

Huawei’s 4.5 GWh Terra Solar project proves technical viability at scale:

<1> 40,000 tons annual diesel displacement;

<2> <3-minute blackout recovery via grid-forming inverters.

*Table: Rural Solar-Storage Microgrid Performance Metrics (2025)*

| Region | Installed Capacity | Households Served | Cost Reduction | Emission Reduction | Job Creation |

| Rajasthan, IN | 463 MW | 667,000 | 37% | 85.3% | 189,000 |

| Shandong, CN | 68 MW | 12,500 | 42% | 91% | 3,200 |

| Central Kenya | 18 MW | 38,400 | 51% | 97% | 860 |

Sources: GEAPP Report 2025, State Grid Linyi Data.

Q&A: Technical Insights from the Frontier

Q1: How do modern microgrids handle 3-day cloud coverage?

“Hybrid controllers blend solar, storage, and bio-generators (e.g., rice husk CHP). Our systems maintain 99.97% uptime in monsoon zones via multi-day state-of-charge forecasting—drawing only 5% backup fuel versus 40% in legacy setups.” – MateSolar CEO

Q2: Can village systems support heavy agricultural machinery?

“Absolutely. Our 480V industrial blocks deliver 200 kVA continuous power using silicon carbide inverters. In Ningxia, China, 15-kW almond processing units run directly on solar-storage during peak hours.”

Q3: What cybersecurity measures exist for distributed systems?

“Zero-trust architecture with hardware-secured modules (HSMs) and blockchain-verified firmware updates. Each device has a unique cryptographic identity—no ‘master key’ vulnerability.”

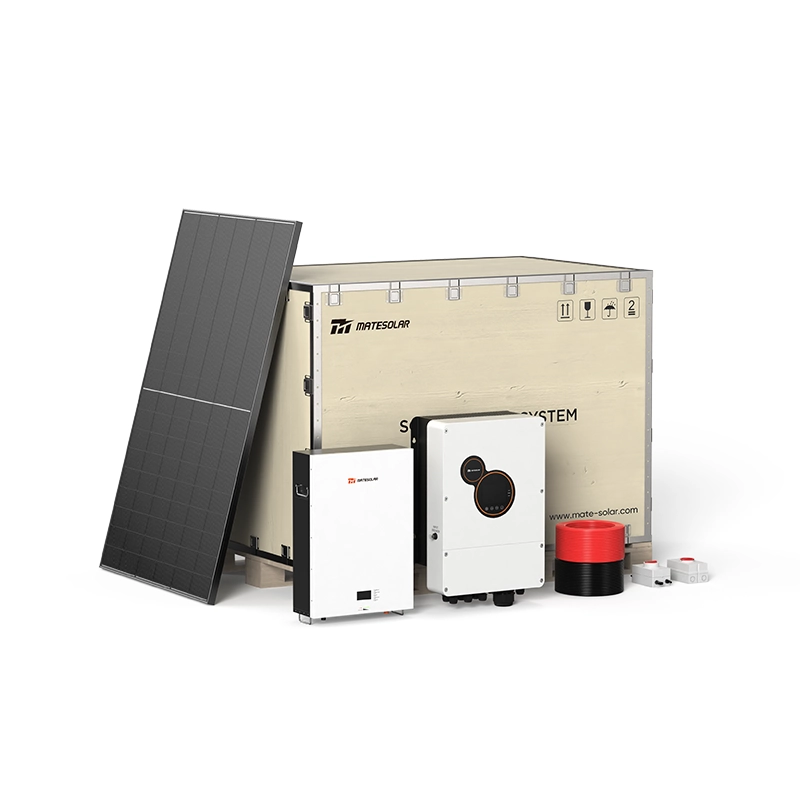

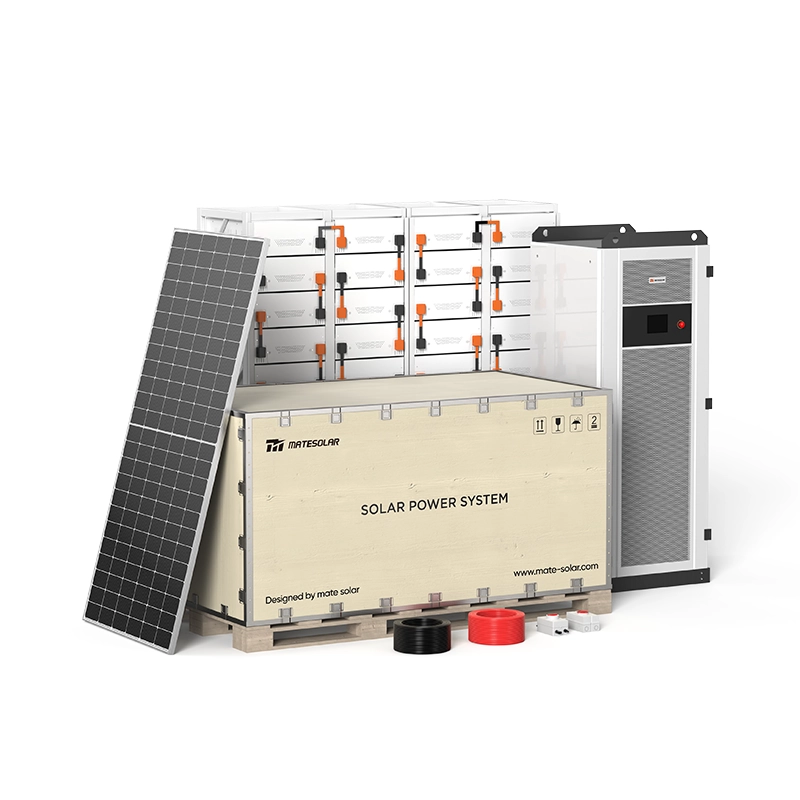

The MateSolar Advantage: Integrated Power Ecosystems

Born from 15 years of field deployments across 47 countries, MateSolar delivers all-in-one microgrid solutions featuring:

1. HyperStack™ Batteries: Module-level optimization boosting lifecycle throughput by 15% via patented active balancing;

2. CropSync™ AI Controller: Integrates weather, crop prices, and grid signals to maximize farmer income;

3. Community Ownership Models: 20-year asset management with local equity participation.

“While others sell panels, we sell prosperity. Our systems in Zambia increased tomato yields by 300% simply by enabling 24/7 cold storage—proving energy access isn’t just about watts, but wealth creation.”

— Mr. Quke, CEO, MateSolar