The convergence of agriculture and solar energy generation is revolutionizing sustainable farming practices worldwide. Modern agrivoltaics—the strategic co-location of crop production and solar photovoltaic systems—has evolved far beyond simple rooftop installations to become sophisticated climate-smart infrastructure. By creating synergistic microclimates that boost crop resilience while producing clean electricity, these dual-use systems are answering the global challenge of land competition between food and energy production. With the agrivoltaics market accelerating at 15% CAGR and projected to reach $12.3 billion by 2032, agricultural solar solutions represent not merely an innovation but an operational necessity for forward-thinking farmers navigating climate uncertainty and resource scarcity

The Evolution of Agrivoltaic Technology

Early solar farming concepts treated panels and plants as competing interests, but contemporary systems engineer their symbiosis. Research confirms that strategically spaced elevated PV arrays create optimized microclimates—reducing midday photosynthetically active radiation by 75%, lowering ambient temperatures by 1.3°C, and decreasing vapor pressure deficit by 0.5 kPa. These conditions significantly mitigate "photosynthetic midday depression," where crops typically shut down stomatal activity under heat/light stress. Trials demonstrate 11.7%-45.8% increased daily net CO₂ uptake in tomatoes and beans, even under 50% reduced irrigation—proving solar shelters enhance both water efficiency and carbon assimilation

The grid integration challenge has been transformed by true grid-forming (GFM) capabilities, now extending beyond storage to full PV-plus-storage ecosystems. Huawei's pioneering FusionSolar 9.0 solution exemplifies this shift with six core technical breakthroughs: short-circuit current support, virtual inertia emulation, wide-band oscillation damping, sub-second primary frequency response, minute-scale black start, and seamless grid-islanding transitions. These allow stable operation even at near-zero grid strength (SCR=1.0)—critical for remote farms with weak infrastructure

Table: Performance Improvements Enabled by Advanced Agrivoltaic Systems

| المعلمة | Traditional Farming | With Agrivoltaics | Improvement |

| Midday PAR Reduction | 0% | 75% | N/A |

| Daily CO₂ Uptake (Tomatoes) | Baseline | +11.7% to 45.8% | ↑ 45.8% max |

| Water Productivity | Baseline | +112% to 130% | >2x increase |

| Yield Under 50% Irrigation | -59% (Tomatoes) | Stable (Tomatoes) | Prevents loss |

| O&M Efficiency | Manual | AI-optimized | ↑ 50% |

Next-Generation Agrivoltaic Solutions

Spectral Harvesting and Adaptive Design

Swiss innovator Voltiris has cracked the code on greenhouse compatibility with its wavelength-selective PV systems. Using rooftop dichroic mirrors, sunlight is split into spectra:

photosynthetically active wavelengths (400-700nm) pass through to crops, while near-infrared light is concentrated onto silicon panels. This achieves peak power outputs of 145 W/m² without causing the >70% light loss typical of opaque overhead PV—making it viable for high-value greenhouse operations.

Elevation and spacing parameters are equally critical. Trina Solar’s Japan project demonstrates optimal configuration: panels mounted ≥2.35 meters high with row spacing accommodating farm machinery. Under this partial-shade environment, shade-tolerant crops like Japanese yam (ebi-imo) thrive due to reduced photoinhibition and soil moisture conservation—yielding simultaneous energy harvest and agricultural output.

Biodegradable Energy Harvesters

Finnish researchers at VTT Technical Research Centre have developed ultra-thin (<35μm) biodegradable solar modules from bio-based composites. Credit-card-sized units adhere directly to plant stems or leaves, powering IoT sensors throughout the growing season before harmlessly decomposing. This eliminates retrieval logistics and prevents persistent e-waste in fields—solving a major hurdle for precision agriculture’s expansion.

Market Expansion and Critical Applications

Solar-powered irrigation dominates the agrivoltaics market, projected to grow from $4.02B in 2024 to $12.3B by 2032. Drip irrigation captures >50% share due to its water efficiency synergy with PV power—converting each drop into maximal yield. Significantly, small-scale systems (<5kW) lead adoption (38.5% revenue share), though 5-15kW mid-range solutions are growing fastest (16.2% CAGR) as farmers scale deployments.

Table: Solar Irrigation System Market Outlook (2024-2032)

| Segment | 2024 Value | 2032 Projection | CAGR | Notes |

| Overall Market | $4.02B | $12.3B | 15.0% | Driven by water scarcity |

| By Capacity | ||||

| <5 kW | $1.55B | $4.3B | 13.6% | 38.5% current share |

| 5-15 kW | $1.04B | $3.8B | 16.2% | Fastest growing segment |

| By Application | ||||

| Agriculture | $2.41B | $7.38B | 15.0% | 60% market share |

| Horticulture | $1.00B | $3.08B | 15.1% | Greenhouse focus |

Real-World Implementations and Benefits

Arizona researchers validated agrivoltaics’ drought resilience by comparing tomato and bean yields under 50% irrigation. Traditional farms saw 59% yield collapse, while AV plots maintained stable production—proof that microclimate buffering reduces crop water stress. The mechanism is twofold: cooler temperatures lower evapotranspiration demand while shaded soil retains moisture longer. Combined, these cut total farm water needs by 30-50% without sacrificing output.

Japan’s utility-scale agrivoltaics prove the model’s scalability. Trina Solar’s Kyoto installation combines 3,392 high-efficiency panels (23.2% efficiency) with yam cultivation across a single unified site. Generating 2,700 MWh annually—enough to power 600 homes—while reducing CO₂ by 1,760 tonnes, the project exemplifies land-use optimization. Japan now targets 25% of solar generation from farmland by 2050.

Even water bodies are being leveraged through floating PV farms. Singapore’s 150 MW Kranji Reservoir project powers Meta’s data centers via 25-year PPA agreements—demonstrating how corporations can drive agri-solar adoption. With Sembcorp developing similar farms across Southeast Asia, these installations avoid land competition entirely while reducing reservoir evaporation.

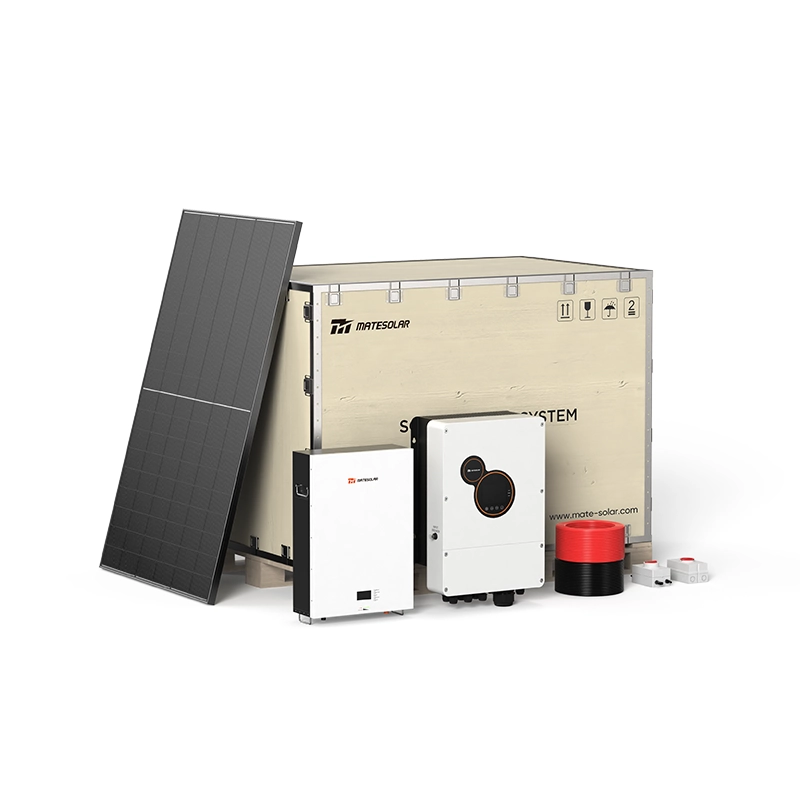

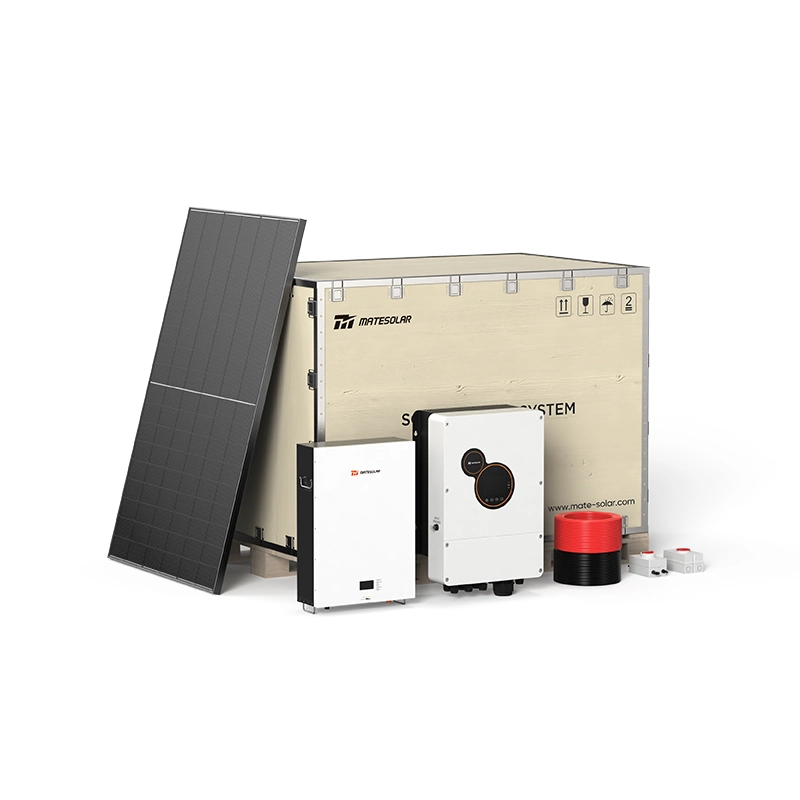

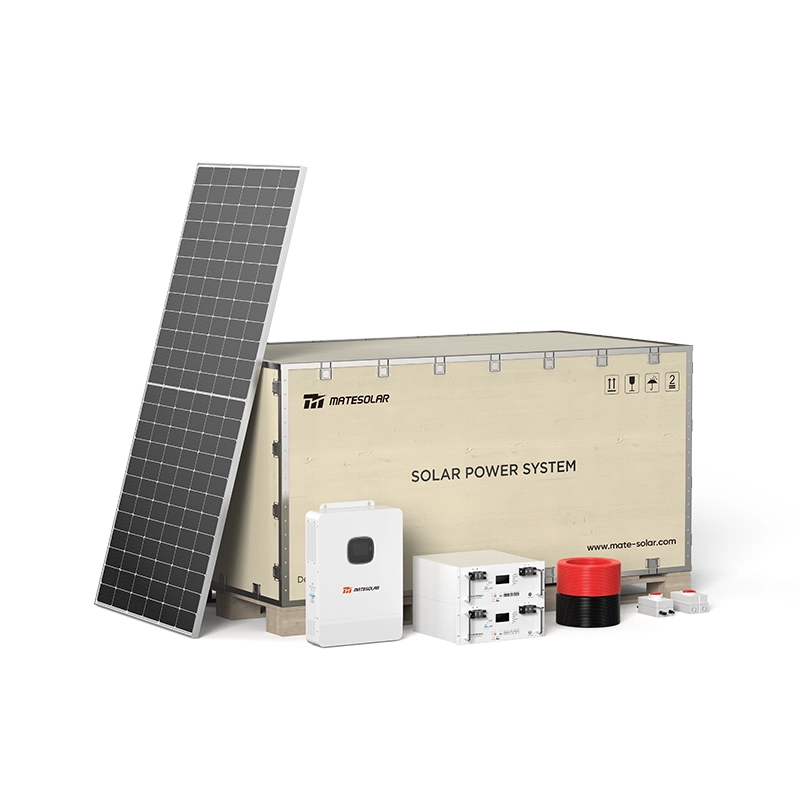

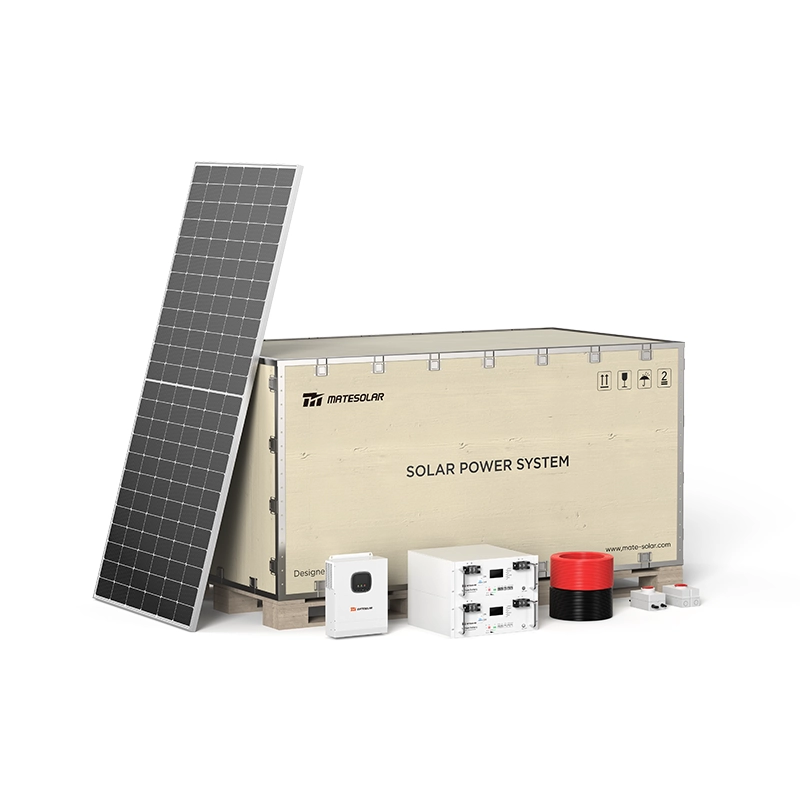

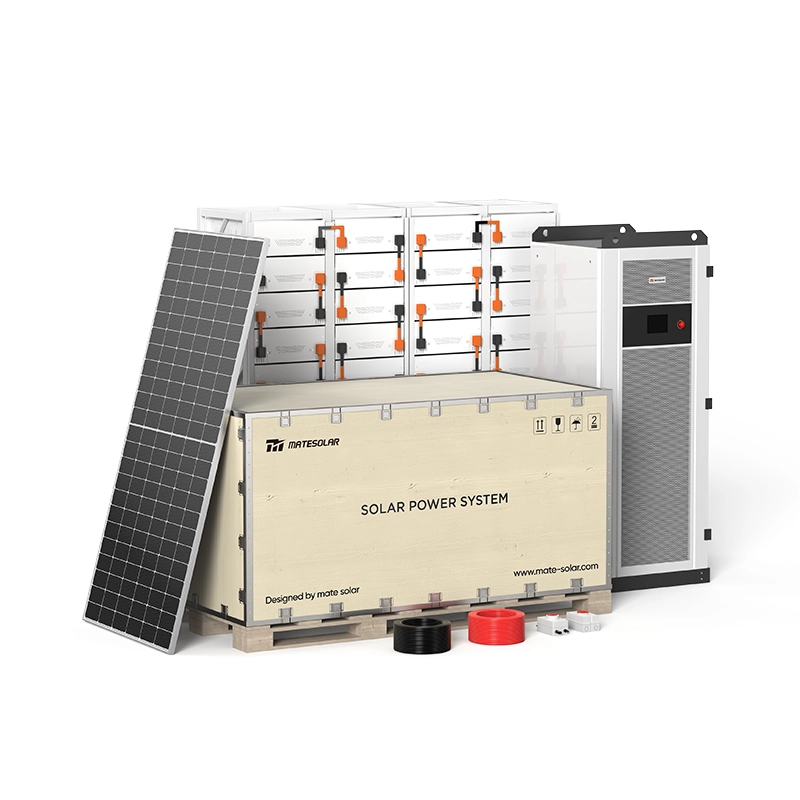

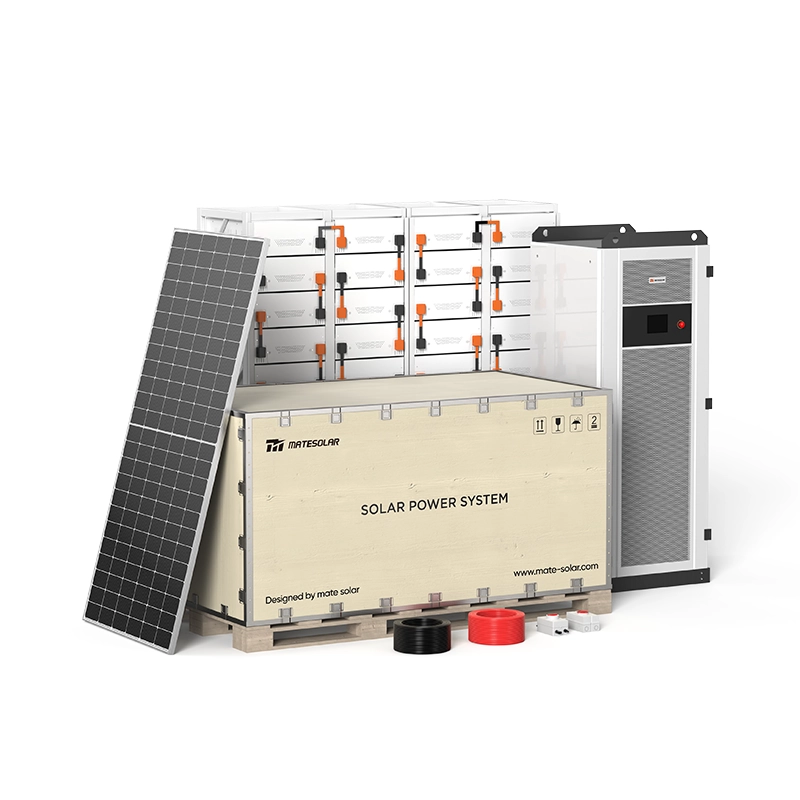

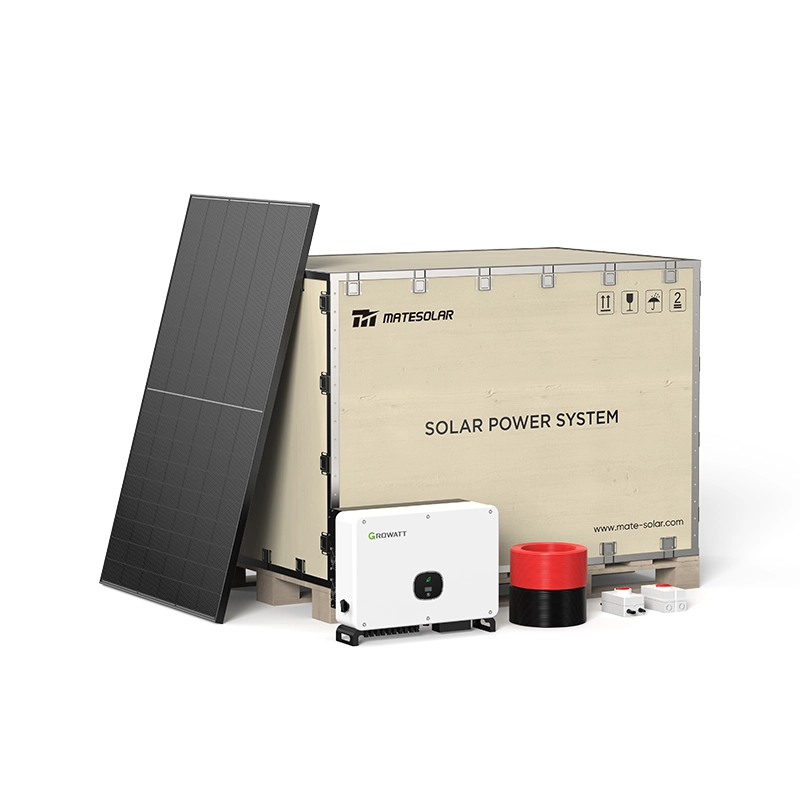

MateSolar: Integrated Agri-Voltaic Solutions

At MateSolar, we fuse next-generation GFM storage, AI-driven management, and spectral-optimized PV to deliver comprehensive farm-energy ecosystems. Our modular solutions feature:

- Dynamic Grid-Forming Storage: Huawei-inspired multi-inverter parallel control for SCR-independent operation, enabling farms to run stably even in weak-grid rural areas.

- Crop-Specific Spectral Tuning: Voltiris-mirrored wavelength engineering for greenhouses or open-field spectral splitting.

- AI Microclimate Optimization: FusionSolar Agent predictive algorithms balancing irradiance, temperature, and VPD in real-time to prevent photosynthetic suppression.

- Water-Energy Synergy: Solar irrigation controllers that cut pumping energy by 70% while implementing precision soil moisture scheduling.

Q&A: MateSolar System Capabilities

Q: How does MateSolar address partial shading in uneven fields?

A: Our module-level power electronics (MLPE) incorporate DC optimizers that mitigate mismatch losses. Each panel operates independently, ensuring 99.5% shade tolerance while supporting 1500V strings—critical for farms with terrain variations or intermittent shading.

Q: Can your systems withstand harsh farm environments?

A: Absolutely. We utilize IP68-rated enclosures, corrosion-resistant aluminum frames, and glass-glass bifacial panels rated for ammonia exposure. Optional nanoparticle coatings repel dust accumulation, maintaining >95% performance after 5 years in feedlot-adjacent deployments.

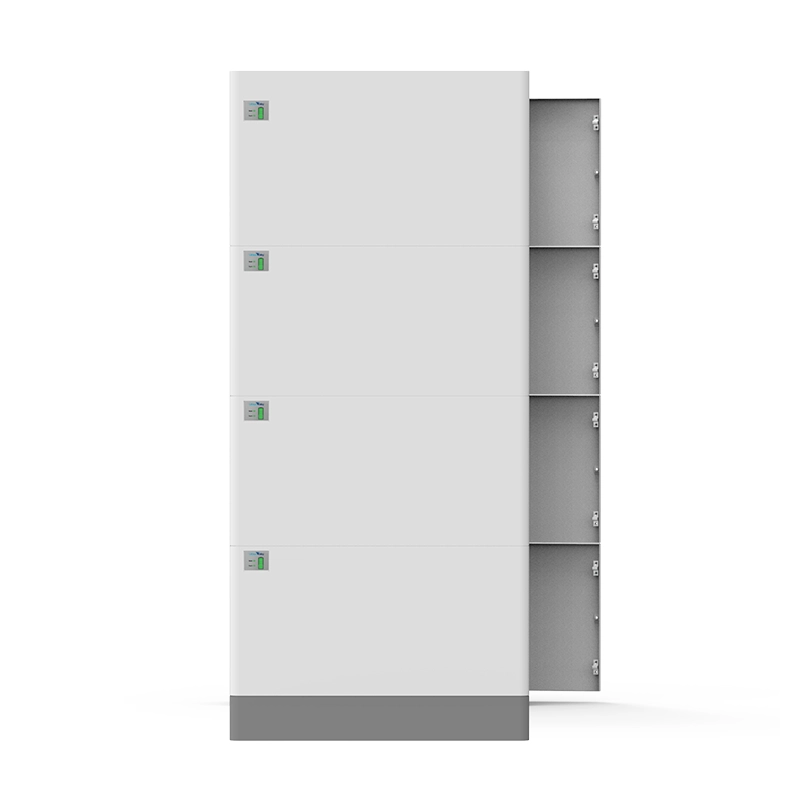

Q: What safety measures prevent thermal runaway in battery systems?

A: Our five-layer protection starts with UL9540A-certified LFP cells, proceeds to pack-level "Rock" reinforced structures with directional venting, and culminates in cloud-based thermal runaway early warning (accuracy >90%). Multi-level breaker coordination disconnects faults within 2ms.

Q: How does AI enhance operational efficiency?

A: FusionSolar Agent’s digital twin models predict yield impacts from panel configurations. By analyzing satellite imagery, weather data, and soil sensors, it recommends layout adjustments to gain 5-8% more light for crops while optimizing tilt angles for energy—proactively balancing both outputs.

Q: Are biodegradable electronics available?

A: We now offer VTT-inspired compostable sensors powered by thin-film solar patches. These $15/node units monitor microclimate conditions for 6-9 months before biodegrading—perfect for seasonal field monitoring without retrieval costs.

The agricultural energy revolution is here—where every hectare simultaneously harvests photons for clean power and food. With MateSolar’s integrated platforms, farms transform from energy consumers to precision-balanced generators—resilient against climate shocks while profitably feeding grids and communities.

Contact MateSolar today to commission your dual-use energy farm—where sustainability is measured in both kilowatts and kilograms.

MateSolar: Integrated Agrivoltaic Systems for the Zero-Carbon Farm.